Where stored grain beetles come from (GRDC Ground Cover May 2017)

Source Link GRDC

Key points

- Grain is most likely to be infested by beetles from your storage facility

- Effective hygiene can delay infestation for at least two months

- Beetles typically fly within a two-kilometre radius to infest another grain storage

- Some beetles can fly more than 100km to infest grain

- Flying beetles are spreading insecticide resistance over large areas

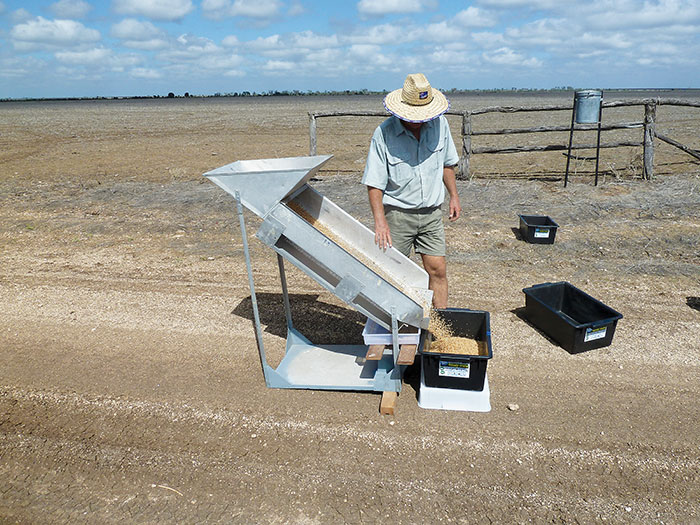

A mini silo filled with 50 litres of wheat set up near existing farm storage.

PHOTO: Dr Andrew Ridley

Infestation of stored grain can sometimes seem inevitable, but storage pests are reliant on a food source that we control. Too often we provide a friendly environment for these pests by failing to detect and deal promptly with infested grain, or clean out empty silos and equipment.

If we are ever going to reduce our reliance on killing pests once they have infested grain, we need to better understand the insects and how they infest our grain storage in the first place.

The results from research conducted on Australian grain farms by the Queensland Department of Agriculture and Fisheries and the University of Queensland offer some helpful instructions for grain storage best practice.

Harvested grain placed into a silo can become infested from two potential sources. First, there may be a residual pest population hiding in grain handling machinery or silos that will be incorporated into freshly harvested grain. Second, pests can move into the grain of their own accord by flying in from infested silos.

A common misconception is that pests are brought in with the crop at harvest time and this is when infestation starts. It is true that insects such as grasshoppers and lady beetles are harvested along with grain, but these field crop pests die quickly in the dry conditions of stored grain.

The majority of stored grain beetles do not infest standing crops, so this is not likely to be the source of the problem. Only if you are harvesting legumes or maize should you be concerned about gathering up unwanted storage pests with your grain.

When harvesting legumes or maize, keep an eye out for adult beetle exit holes (these are hard to miss) or small white eggs glued to the surface of the seeds in grain samples. Also, use an insect sieve for maize and legumes as you are filling silos during harvest. Get pests identified correctly to see if they are field pests or storage pests. When storage pests are detected during harvest, aerate grain initially over the first two weeks to provide safe uniform grain storage conditions, then seal the silo to fumigate pests. Once pests are killed, return to aeration.

Residual pest populations

Dr Philip Burrill of Queensland DAF sieving grain from a mini silo placed 2km from farm storage in Mount McLaren.

PHOTO: Dr Andrew Ridley

Most grain storage beetles are long-lived and can survive on very small amounts of food. Grubs of the red flour beetle (Tribolium castaneum) can survive on the thin layers of grain dust that settles on flat surfaces.

It can be difficult, therefore, to eradicate pests from machinery and storages unless these structures are specifically designed to assist in cleaning. Some silos are made with flat internal surfaces so grain and dust have nothing to cling to. Flat bottom silos with ‘full floor’ aeration are, in contrast, not easy to clean. Removing grain residues in the subfloor area is difficult. Some manufacturers provide a flat bottom silo with channel aeration systems that are simple to clean and just as effective for aeration cooling.

When purchasing new grain storage, take hygiene into account. The silo will be there for a long time and the easier it is to clean the more likely you are to do it.

Grain-handling machinery that contains small amounts of grain can be a source of pests. One header we sampled was hiding more than 1000 lesser grain borers (Rhyzopertha dominica) waiting to be mixed with freshly harvested grain.

Headers, augers, grain dryers and other grain-handling equipment can be cleaned with compressed air and then dusted with a diatomaceous earth product such as Dryacide® to kill any remaining pests.

Likely sources of pests

If you have an existing infestation somewhere at your grain storage facility, your freshly harvested grain will most likely become infested with beetles quickly.

One of the beetle traps set one kilometre from grain storage that caught storage pests flying from one farm to another.

PHOTO: Dr Andrew Ridley

We placed wheat in mini silos (50-litre capacity) near farm silos in central Queensland and sieved the grain after two months. We also looked for pests in the storages on each farm. We found that where a farm already had a particular pest species in storage facilities, it usually infested the clean grain in our nearby mini silos quickly.

We also found that the mini silos were unlikely to become infested by pest species that were not already present on the farm. This demonstrated that hygiene, when done well, can delay the onset of infestation by at least two months. For grains harvested in spring, delaying infestation beyond summer can greatly reduce the need to control pests once temperatures drop in winter and pests are less likely to be flying.

Disposal of old and waste grain that tends to be heavily infested will make the greatest impact on the number of pests in your storage facility.

Even small parcels of grain can produce huge numbers of pests. When 100 beetles each of six pest species were introduced into a 27-kilogram box of wheat, more than 1.5 million beetles were produced over the course of a year. Most of these beetles were caught leaving the infestation.

But how far away do you need to dump waste and infested grain? If possible it is always best to bury, burn or spread (less than 10 millimetres deep) infested waste grain.

Grain in mini silos, which were placed two kilometres away from a storage facility was much less likely to be colonised by flying beetles. Therefore, if possible, separate infested grain from grain you wish to sell insect-free by at least two kilometres. This will significantly decrease the risk of infestation from flying storage pests.

Mixed farming operations have particular challenges in terms of insect-free grain storage. Feed mills are difficult to keep pest free because the continuous flow of grain makes sealing silos for fumigation difficult.

The labour involved in cleaning hoppers and augers leads to exposed parcels of grain highly likely to contain storage pests. If I go to a farm looking for storage pests and see a feed mill, the hopper is the first place I look. Storage piles of cotton seed are also a favoured site for the red flour beetle, a common pest of grain in storage.

Figure 1 Mean (± standard error) number of lesser grain borer (Rhyzopertha dominica) beetles caught in 15 traps baited with R. dominica pheromone lures located at farm storages (red) and in paddocks at least one kilometre from those storages (orange). Traps were active for seven days at each sampling period.

If feed mills and stored commercial grain are co-located, grain protectants can be used on feed grain to reduce the chance of these grains becoming breeding grounds for storage pests. Always check the chemical label and discuss chemical application with potential buyers prior to applying any grain protectant treatments.

It is easy to wonder how you ended up with infested grain despite doing a thorough job of hygiene. Unfortunately, just as pests are moving from silo to silo within a complex, they are also moving between properties. We showed this in southern Queensland, where we set up traps for flying beetles in paddocks at least 1km from farm storage, typically along fencelines. We caught lesser grain borers and red flour beetles throughout the year (Figure 1).

So what you and your neighbours do to manage stored grain pests will have an impact on everyone.

Resistance moves with beetles

The ability to manage grain storage pests with grain protectant insecticides and the fumigant phosphine is extremely valuable to the Australian industry. Nil tolerance for live pests is the standard for receival, so tools to deal with storage pests are crucial.

One of the big downsides of beetles moving from one grain storage to another is the potential spread of resistance to control tools. Long-term storage of grain that relies on multiple applications of phosphine or over-reliance on one type of grain protectant – or ineffective fumigation due to silos not being sealed correctly – will result in selection for resistant populations that are harder to kill. These difficult-to-control pests then fly off and infest other parcels of grain.

We can measure the relationships of beetles from different farms using genetics. What we found, after sampling farms in the Southern Downs district of Queensland, is that there has been enough movement to make all beetles from an area of more than 4000 square kilometres become part of ‘one big family’.

This means when one person does the wrong thing and allows selection for resistance, these harder-to-kill beetles are moving to other farms. Using this population genetics technique we estimate that some beetles have travelled more than 100km.

The movement of resistance genes is particularly important when we consider the rusty grain beetle (Cryptolestes ferrugineus). This beetle has become very difficult to kill with phosphine compared with other pests.

Stored grain beetles are hard to control, but with access to treatments and quality storage, Australian growers are some of the best at delivering high-quality grain. Better planning to limit the pressure of insect infestation on your grain will help protect our current treatments and maintain Australia’s good reputation.

More information:

Dr Greg Daglish,

07 3708 8538,

greg.daglish@daf.qld.gov.au

Philip Burrill,

0427 696 500,

philip.burrill@daf.qld.gov.au

GRDC Project Code Plant Biosecurity Cooperative Research Centre Codes CRC50089, CRC50149, CRC3039

Region National

Stored Grain Pests Identification – The Back Pocket Guide

This identification guide provides a snapshot of common pests found in stored grain in Australia. The tolerance for live storage pests in grain sold off-farm either for the domestic, humanconsumption market or for the export market is nil. With more grain being stored on-farm growers need to identify pests early and monitor – at the very least – monthly. Regular inspection by sieving grain from the top and bottom of silos will provide an early warning of insects present.

Lesser Grain Borer

A serious pest of most stored grains: the Lesser Grain Borer has developed resistance to a number of grain insecticides.

KEY FEATURES:

- Dark brown cylindrical shaped beetle (up to 3mm long) with club-like antennae

- Viewed from the side the beetle’s mouth parts and eyes are tucked underneath the thorax (chest)

- Adult beetles are strong flyers.

LIFE CYCLE:

- Life cycle completed in four weeks at 35°C and seven weeks at 22°C. Breeding stops below 18°C

- Females lay between 200 – 400 eggs on grain surface. Young larvae (white with brown heads) initially feed outside then bore into the grain

- Adults live for 2 – 3 months.

DETECTION:

- Their habit is to remain hidden in grain. Regular sampling and sieving is required for detection.

Rust-Red Flour Beetle

Commonly found in stored cereal grain, processed grain products, oilseeds, nuts and dried fruit.

KEY FEATURES:

- Adult beetles (3 – 4.5mm long) bright reddish-brown in colour

when young and a darker brown when older - Three larger segments on end of end of antennae

- Similar species: Tribolium confusum – confused flour beetle, more

common in cool, temperate regions.

LIFE CYCLE:

- Life cycle completed in 4 weeks at 30°C, 11 weeks at 22°C and

reproduction stops below 20°C - Adults live from 200 days to 2 years and fly in warm conditions

- Up to 1000 eggs per female, loosely scattered throughout the

commodity - Cream-coloured larvae feed externally on damaged grain

- Beetles infest whole grain, but breed more successfully on

processed products (i.e. flour).

DETECTION:

- Beetles move quickly and are strong flyers. When in low numbers

use sieving and probe traps to detect - Prefered habit is around storage areas with poor hygiene, broken grain, gradings or bulk cottonseed.

Rice Weevil

Major pest of whole cereal grains.

KEY FEATURES:

- Adults are dark brownish black (2 – 4mm long) with a long weevil ‘snout’

- Have four small light coloured patches on its rear wing covers

- Rarely flies, but climbs vertical surfaces (e.g. glass jar)

- Similar species: Sitophilus zeamais – maize weevil,

and Sitophilus granarius – granary weevil.

LIFE CYCLE:

- Adults live 2-3 months

- Larvae generally not seen – they feed and develop inside single grains

- Life cycle completed in four weeks at 30°C, 15 weeks at 18°C, breeding stops below 15°C.

DETECTION:

- Under warm conditions or when grain is moved rice weevils are often observed climbing out of grain up vertical surfaces. Sieving & probe traps recommended to detect low numbers.

Flat Grain Beetle

Infests most stored grain and feeds on damaged grain. Some populations have high levels of phosphine resistance.

KEY FEATURES:

- Smaller than other major stored grain pests (2mm long), very flat,reddish brown colour with long thin antennae

- Fast moving, seeking cover under grain or trash

- Adults fly readily and can live for several months

- C. ferrugineus most common in Australia, but there are several closely related Cryptolestes species with similar appearance.

LIFE CYCLE:

- Life cycle completed in 4 weeks at 30 – 35°C with moist conditions, 13 weeks at 20°C, breeding stops at 17.5°C

- Larvae, with characteristic tail and horns, feed and develop externally on damaged grains

- Females lay up to 300 eggs loosely in the grain stack.

DETECTION:

- Sieving and probe traps usually required for detection

- Some populations of flat grain beetles have developed very high levels of phosphine resistance. Send in insect samples for testing after a fumigation failure.

Saw-Toothed Grain Beetle

Infests cereal grains, oilseeds, processed products, peanuts and dried fruits.

KEY FEATURES:

- Dark brown-black beetle (up to 3mm long), fast moving

- Thorax (chest) has saw-toothed pattern on each side and three distinct ridge lines on top

- Adults climb vertical surfaces (glass jar) and fly in warm conditions.

LIFE CYCLE:

- Prefers damaged or processed grain to establish in significant numbers

- Adults can live for several months, females laying 300 – 400 eggs loosely throughout the grain. White larvae feed and develop externally

- Life cycle completed in 3 weeks at 30 – 33°C, 17 weeks at 20°C, reproduction stops below 17.5°C.

DETECTION:

- Sieving and probe traps are recommended for detection

- Has developed resistance to a number of grain insecticides.

Psocids – Booklice

Infests a wide range of grains, commodities and storage facilities.

KEY FEATURES:

- Very small, soft-bodied and opaque, pale coloured (up to 1mm long), often appear as a ‘moving carpet of dust’ on grain or storage structures

- A secondary pest, feeding on damaged grain and moulds

- There are three main species of psocids in Australia, often in mixed populations.

LIFE CYCLE:

- Thrive under warm, moist conditions – optimum 25°C and 75% relative humidity. Life cycle 21 days

- Eggs are laid on grain surface, hatching to nymphs that moult through to adult stage.

DETECTION:

- Warm, humid conditions increases activity. Usually observed in storage or on grain surfaces. Sample and sieve to detect when in low numbers.

BRUCHIDS: Cowpea weevils

Callosobruchus spp are pests of most pulse crops, including mungbeans, cowpeas, field peas, chickpeas, soybeans and lentils.

KEY FEATURES:

- Adults (up to 4mm long), emerge through perfectly round holes in the seed

- Globular, tear-shaped body is reddish brown with black and grey markings

- Wing covers (elytra) do not fully cover the abdomen

- Adults have long antennae, climb vertical surfaces (glass jar) and are strong flyers.

LIFE CYCLE:

- Adults do not feed, but lay 100 white eggs clearly visible on the outside of seed. Adult short lifespan 10 –12 days. Unlike most storage pests, adults may also lay eggs on mature seed pods in a standing crop

- Larvae feed and develop within individual seeds and emerge as adults leaving a neat round hole.

DETECTION:

- A common problem in warmer months for mungbeans.

Fortnightly thorough sampling and sieving is important to prevent serious losses.

Pea Weevil

Both a field pest and storage pest (appears in storage after emergence). In WA it is a major pest of field peas.

KEY FEATURES:

- Adult globular body length (4 – 5mm long) with long legs and antennae

- Wings (elytra) are patterned with white/cream spots

- Do not breed in stored dry peas, adults lay and glue eggs onto pods in standing pea crops before harvest

- Adult emerges through a neat round hole in the seed

- Adults are strong flyers, they reappear in spring to visit flowers to feed on the nectar then seek out new field peas crops to lay eggs.

LIFE CYCLE:

- Hatching larvae bore through the seed pod and into a single seed where they feed, grow and pupate

- Breed one generation per year. Adult is long-lived and overwinters but does not feed on field peas.

DETECTION:

- Adults migrate into crops from seed sources and nearby trees where they shelter under the bark

- Field peas should be regularly checked, in and around the crop edges when first pods are forming using a sweep net when temperatures are above 18°C

- Check pea seed for neat round holes (evidence that adults have emerged).

MOTHS: Angoumois Grain Moth

A pest of whole cereal grains which only infests surface layers of bulk-stored grains. Infestation of standing maize crops before harvest is quite common, occasionally in other cereal crops.

KEY FEATURES:

- Silvery grey to grey brown wings which taper to a point

- Wings have a long fringe of fine hairs along the posterior edge

- Adults (5 – 7mm long) are unable to penetrate grain, therefore only infest surface layers of bulk grain.

LIFE CYCLE:

- Adult moths do not feed but lay 150 – 300 eggs on or near the grain surface. This pest does not create webbing

- Larvae burrow into a single grain and feed and develop until the adult moth emerges in 10 – 14 days through a visible hole

- Life cycle takes around 5 – 7 weeks in warm conditions.

DETECTION:

- Take regular monthly samples and look for moths near grain surface. When adults emerge pupal cases are often found protruding from grain.

Indian Meal Moth

A pest in flour mills, processing plants, dried fruit and on the surface of all types of grains.

KEY FEATURES:

- Adults (5 – 7mm long), distinctive bicoloured wings – dark reddish brown on rear half of the wing and grey at the front.

LIFE CYCLE:

- Female month lay 200 – 400 eggs on the foodstuff

- Larvae create webbing as they feed. They then pupate in several grains webbed together in a clump

- In summer life cycle takes about 4 weeks.

DETECTION:

- Take regular monthly samples and look for webbing and moths near grain surface

- Also check in residues on grain harvesting and handling equipment.

Warehouse Moths

A pest of flour mills, food processing plants, cereal grains and oilseeds.

KEY FEATURES:

- Adult moth body length is 8 – 10mm

- Moth has grey wings with many fine, dark wavy markings, including lighter stripes extending horizontally across each forewing

- Extensive webbing created by larvae is visible on the grain surface.

LIFE CYCLE:

- Adult moths do not feed and are short-lived. Female lays between 100 – 270 eggs over a two week period on or near grain

- Caterpillar is coloured light pink with a small black spot at the base of each hair

- Full life cycle 30 days under ideal conditions, 30°C and 75% relative humidity.

DETECTION:

- Take regular monthly samples and look for webbing and moths near grain surface. All moths are typically active at dusk and dawn.

Phosphine-Resistant Insects

- Saw-Toothed Grain Beetle and Lesser Grain Borer have developed some resistance to a number of grain insecticides.

- Flat Grain Beetle: some populations (Rusty Grain Beetle) have developed high level of phosphine resistance.

- A range of stored grain insects are becoming harder to kill with phosphine fumigations.

- Threatens exports, as phosphine may become ineffective against some pests.

- Poor fumigation practices increase resistance (e.g. repeated fumigations in unsealed or poorly sealed storages).

- Strong phosphine resistance is also found in overseas countries.

- Live insects detected following fumigation should be tested for resistance.

- Resistant insects can fly between stores or be transported in machinery.

EXOTIC PESTS: NOT PRESENT IN AUSTRALIA

BE ON THE LOOKOUT

The following pests have serious potential impact on the value of grain if detected in Australia. If you see anything unusual, report it to your local state department of primary industries or phone the Exotic Plant Pest Hotline, 1800 084 881

Karnal bunt

(Tilletia indica)

- Can infect wheat, durum and triticale.

- Usually only part of each grain is affected. Infected stored grain will have a sooty appearance and will crush easily, leaving a black powder.

- Infected grain often has a rotten fish smell, flour quality is seriously reduced.

- Symptoms are similar to common bunt.

How to monitor and identify grain pests

- Identify pests early by regular fortnightly/monthly sampling

- Sieve (with 2mm mesh) grain samples taken from the top and bottom of stores onto a white tray. Hold tray out in sunlight to warm for 10 to 20 seconds to encourage insect movement to identify them.

- Also use grain probes or pitfall traps to monitor for insects. These are pushed into the grain surface and then pulled up for fortnightly/monthly inspection. Place 1 or 2 traps in the top of a silo or several traps in a grain shed.

- If live insects are found, identify them and select the appropriate treatment for the grain type and insect. Always check product labels. Ensure potential grain buyers & end-users also accept treatments selected.

To check insects for resistance, send samples for testing

FOLLOW THESE BASIC STEPS:

- Use a small, strong plastic container which is well sealed. DO NOT provide air holes – insects will escape

- Place 20 to 100 insects with clean untreated grain into container

- Do not overfill the container – leave some air space

- Label container with the date, your name and the silo/storage identification

- Provide all your contact details (address, phone and email) and a brief explanation of why you are seeking a resistance test, the storage type and details of any

grain treatments details - If possible post early in the week so the insects are not left in the mail over the weekend.

SEND SAMPLES TO YOUR RELEVANT REGIONAL AUSTRALIAN LABORATORY:

NORTHERN REGION (QLD AND NORTHERN NSW):

Dr Manoj Nayak

DAF

Ecosciences Precinct

GPO Box 267

Brisbane Qld 4001

E: manoj.nayak@daf.qld.gov.au

SOUTHERN REGION (SOUTHERN NSW, VIC, SA AND TAS):

Please phone 02 6938 1605 before sending sample

Dr Joanne Holloway

NSW DPI / Wagga Wagga Agricultural Institute

Pine Gully Rd

Wagga Wagga NSW 2650

E: joanne.holloway@dpi.nsw.gov.au

WESTERN REGION (WA):

David Cousins

DPIRD Entomology

3 Baron-Hay Court

South Perth WA 6151

E: david.cousins@dpird.wa.gov.au

For WA Biosecurity only WA insects to be sent to this lab!

Grain Fumigation – A Guide

In order to kill grain pests at all stages of their life cycle (egg, larva, pupa, adult), phosphine gas needs to reach, and be maintained at, a concentration possible only in a gas-tight storage.

Key Points

- To control insects at all life stages the only option is to fumigate in a gas-tight storage.

- Cool grain temperatures require a longer fumigation period.

- Aeration fans fitted on gas-tight silos provide a number of benefits including a shorter ventilation period following a fumigation.

The total time required for effective fumigation ranges from 10–17 days, accounting for the minimum exposure period, ventilation and withholding period. This highlights the importance of monitoring grain regularly and at least 17 days before out-loading to allow sufficient time to fumigate if required.

Rates for success

When determining how much phosphine to apply, it is important to treat the entire storage volume, regardless of how much grain is contained inside. For example, a 100 tonne silo full of grain requires 200 phosphine tablets. If that same 100t silo is only half full of grain, it still requires 200 phosphine tablets for effective fumigation.

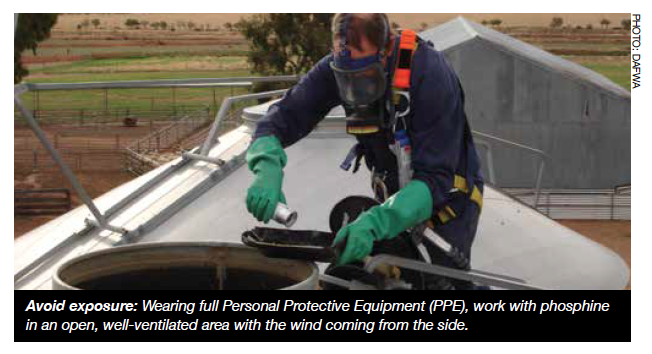

Handle with care

Phosphine is a highly toxic gas with potentially fatal consequences if handled incorrectly. As a minimum requirement, the label directs the use of cotton overalls buttoned at the neck and wrist, eye protection, elbow-length PVC gloves and a breathing respirator with combined dust and gas cartridge.

Where to apply

Arrange the tablets where as much surface area as possible is exposed to air, so the gas can disperse freely throughout the grain stack. Spread phosphine tablets evenly across trays before hanging them in the head space or placing them level on the grain surface inside a gas-tight, sealed silo. Hang bag chains in the head space or roll out flat on the top of the grain so air can freely pass around them as the gas dissipates. Bottom-application facilities must have a passive or active air circulation system to carry the phosphine gas out of the confined space as it evolves. Without air movement, phosphine can reach explosive levels if left to evolve in a confined space.

Time to kill

To control pests at all life stages and prevent insect resistance, phosphine gas concentration needs to reach 300 parts per million (ppm) for seven days (when grain is above 25°C) or 200ppm for 10 days (between 15–25°C). Insect activity is slower in cooler grain temperatures so require longer exposer to the gas to receive a lethal dose.

Table 1 – Application rates for phosphine tablets in storage

Gas venting

Following fumigation, ventilate silos so grain can be delivered free from harmful gas residues. With tablet residue or bag chains removed, leave silos open for no less than five days, or no less than one day with aeration fans

operating. The final step is to hold grain for a further two days after ventilation before using for human consumption or stockfeed

Disclaimer

Any recommendations, suggestions or opinions contained in this publication do not necessarily represent the policy or views of the Grains Research and Development Corporation. No person should act on the basis of the contents of this publication without first obtaining specific, independent professional advice. The Corporation and contributors to this Fact Sheet may identify products by proprietary or trade names to help readers identify particular types of products. We do not endorse or recommend the products of any manufacturer referred to. Other products may perform as well as or better than those specifically referred to. The GRDC will not be liable for any loss, damage, cost or expense incurred or arising by reason of any person using or relying on the information in this publication.

CAUTION: RESEARCH ON UNREGISTERED PESTICIDE USE

Any research with unregistered pesticides or of unregistered products reported in this document does not constitute a recommendation for that particular use by the authors or the authors’ organisations. All pesticide applications must accord with the currently registered label for that particular pesticide, crop, pest and region. Copyright © All material published in this Fact Sheet is copyright protected and may not be reproduced in any form without written permission from the GRDC.

Storing Pulses

Storing pulses successfully requires a balance between ideal harvest and storage conditions. Harvesting at 14 per cent moisture content captures grain quality and reduces mechanical damage to the seed but requires careful management to avoid deterioration during storage.

KEY POINTS

- Pulses stored above 12 per cent moisture content require aeration cooling to maintain quality.

- Meticulous hygiene and aeration cooling are the first lines of defence against pest incursion.

- Fumigation is the only option available to control pests in stored pulses, which requires a gas-tight, sealable storage.

- Avoiding mechanical damage to pulse seeds will maintain market quality, seed viability and be less attractive to insect pests.

Quality characteristics

Pulse crops most commonly grown in Australia include broad beans, faba beans, chickpeas, field peas, lentils, lupins, vetch and mungbeans.

Many of the quality characteristics of the grain from these crops are in the appearance, size and physical integrity of the seed. Mechanical seed damage, discolouration, disease, insect damage, split or small seeds will downgrade quality and market value.

Buyers prefer large, consistently-sized seed free of chemical residues for easy processing and marketing to consumers.

Optimum moisture and temperature

Research has shown that harvesting pulses at higher moisture content (up to 14 per cent) reduces field mould, mechanical damage to the seed, splitting and preserves seed viability. The challenge is to maintain this quality during storage as there is an increased risk of deterioration at these moisture levels. As a result, pulses stored above 12 per cent moisture content require aeration cooling to maintain quality.

Grain Trade Australia (GTA) sets a maximum moisture limit of 14 per cent for most pulses but bulk handlers may have receival requirements as low as 12 per cent. As a general rule of thumb, the higher the moisture content, the lower the temperature required to maintain seed quality (see Table 1).

Green pods and grains increase the risk of mould developing during storage — even at lower moisture content. Aeration cooling will help prevent mould and hot spots by creating uniform conditions throughout the grain bulk.

Weather damage hinders storage

Pulses exposed to weathering before harvest deteriorate more quickly in storage. Chickpeas stored for the medium to long term (6–12 months) continue to age and lose quality

(see Table 2). Growers can minimise the effects of seed darkening, declining germination and reduced seed vigour by:

- Lowering moisture content and temperature

- Harvesting before weather damages the grain.

Aeration cooling — vital tool

Aeration cooling:

- Creates uniform conditions throughout the grain bulk.

- Prevents moisture migration.

- Maintains seed viability (germination and vigour).

- Reduces mould growth.

- Lengthens (and in some instances stops) insect reproduction cycles.

- Slows seed coat darkening and quality loss.

Aeration cooling allows for longer-term storage of low-moisture grain by creating desirable conditions for the grain and undesirable conditions for mould and pests. Unlike aeration drying, aeration cooling can be achieved with air-flow rates of as little as 2–3 litres per second per tonne of grain.

High-moisture grain can also be safely held for a short time with aeration cooling before blending or drying. Run fans continuously to prevent self heating and quality damage.

Be aware that small seeds such as lentils will reduce the aeration fan capacity as there is less space for air to flow between the grains. For information on aeration cooling management, refer to the GRDC fact sheet, Aeration cooling for pest control.

Aeration drying

Pulses stored for longer than three months at high moisture content (>14 per cent) will require drying or blending to maintain seed quality. Aeration drying has a lower risk of cracking and damaging pulses, which can occur with hot-air dryers.

Unlike aeration cooling, drying requires high airflow rates of at least 15–25 l/s/t and careful management. For more information on aeration drying refer to the GRDC booklet, Aerating stored grain, cooling or drying for quality control.

Handle with care

In addition to harvesting at high moisture content, growers can manage seeds quality at harvest by:

- Minimising the number of times augers shift grain.

- Ensuring augers are full of grain and operated at slow speeds.

- Checking auger flight clearance — optimum clearance between flight and tube is half the grain size to minimise grain lodging and damage.

- Operating augers as close as possible to their optimal efficiency — usually an angle of 30 degrees.

- Using a belt conveyor instead of an auger where possible.

Silos fit the bill

Silos are the ideal storage option for pulses, especially if they are cone based for easy out-loading with minimal seed damage. For anything more than short-term storage (3 months) aeration cooling and gas-tight sealable storage suitable for fumigation are essential features for best management quality control.

Silos are the ideal storage option for pulses, especially if they are cone based for easy out-loading with minimal seed damage. For anything more than short-term storage (3 months) aeration cooling and gas-tight sealable storage suitable for fumigation are essential features for best management quality control.

Always fill and empty silos from the centre holes. This is especially important with pulses because most have a high bulk density. Loading or out-loading off-centre will put uneven weight on the structure and cause it to collapse. Avoid storing lentils in silos with horizontally corrugated walls as the grain can run out from the bottom first and collapse the silo as the grain bulk slides down the silo walls.

Pests and control options

The most common pulse pests are the cowpea weevil (Callosobruchus spp.) and pea weevil (Bruchids pisorum). The cowpea weevil has a short life span of 10–12 days while the pea weevil only breeds one generation per year.

The only control options are phosphine, an alternative fumigant or controlled atmosphere, all of which require a gas-tight, sealable storage to control the insects at all life stages.

For more information refer to the GRDC booklet, Fumigating with phosphine, other fumigants and controlled atmospheres.

Chemical sprays are not registered for pulses in any State. While there is a maximum residue limit (MRL) for dichlorvos on lentils, the product is only registered for use on cereal grains.

Weevil development ceases at temperatures below 20°C. This is a strong incentive for aeration cooling, especially if gas-tight storage is not available.

Keep it clean

The first line of defence against grain pests is before the pulses enter storage — meticulous grain hygiene. Because pest control options are limited, it’s critical to remove pests from the storage site before harvest.

The first line of defence against grain pests is before the pulses enter storage — meticulous grain hygiene. Because pest control options are limited, it’s critical to remove pests from the storage site before harvest.

Cleaning silos and storages thoroughly and removing spilt and leftover grain removes the feed source and harbour for insect pests.

Clean the following areas thoroughly:

- Empty silos and grain storages

- Augers and conveyers

- Harvesters

- Field and chaser bins

- Spilt grain around grain storages

- Leftover bags of grain

Chemicals used for structural treatments do not list the specific use before storing pulses on their labels and MRLs in pulses for those products are either extremely low or nil.

Using chemicals even as structural treatments risks exceeding the MRL so is not recommended.

Using diatomaceous earth (DE) as a structural treatment is possible but wash and dry the storage and equipment before using for pulses. This will ensure the DE doesn’t discolour the grain surface.

If unsure, check with the grain buyer before using any product that will come in contact with the stored grain. For more information see the GRDC fact sheet, Hygiene and structural treatments for grain storages.

Grain Storage Insect ID

Grain storage consultant Peter Botta gives useful tips on the monitoring of grain storage insect pests. GRDC Ground Cover TV

Overcoming Phosphine Resistant Insects

For more than 40 years Phosphine has been a safe and reliable means of controlling grain storage insects. Over 80% of stored grain is treated with this chemical but resistance to Phosphine is building amongst insect populations. So when a previously resistant strain of Rust Red Flour Beetle in Western Australia was eradicated by Phosphine it was a remarkable result.

Grain Storage Pest Control Guide – Western Region

The tolerance for live pests in grain sold off farm is nil. With growers increasing the amount of grain stored on farm, an integrated approach to pest control is crucial.

Caution: Research on unregistered pesticide use Any research with unregistered pesticides or of unregistered products reported in this document does not constitute a recommendation for that particular use by the authors or the authors’ organisations. All pesticide applications must accord with the currently registered label for that particular pesticide, crop, pest and region.

KEY POINTS

- Effective grain hygiene and aeration cooling can overcome 85 per cent of pest problems.

- When fumigation is needed it must be carried out in pressuretested, sealed silos.

- Monitor stored grain monthly for moisture, temperature and pests.

Prevention is better than cure

The combination of meticulous grain hygiene plus well-managed aeration cooling generally overcomes 85 per cent of storage pest problems. For grain storage, three key factors provide significant gains for both grain storage pest control and grain quality – hygiene, aeration cooling and correct fumigation.

Hygiene

Hygiene

The first grain harvested is often at the greatest risk of early insect infestation due to contamination. One on-farm test found more than 1000 lesser grain borers in the first 40 litres of wheat passing through the harvester. Remove grain residues from empty storages and grain handling equipment, including harvesters, field bins, augers and silos to ensure an uncontaminated start for new-season grain. Clean equipment by blowing or hosing out residues and dust and then consider a structural treatment (see Table 2, page 3). Remove and discard any grain left in hoppers and bags from the grain storage site so it doesn’t provide a habitat for pests during the off season.

Aeration cooling

Freshly-harvested grain usually has a temperature around 30°C, which is an ideal breeding temperature for storage pests (see Table 1, page 2). Studies have shown that rust-red flour beetles stop breeding at 20°C, lesser grain borer at 18°C and below 15°C all storage pests stop breeding. Aim for grain temperatures of less than 23°C during summer and less than 15°C during winter. When placing grain into storage, run aeration fans continuously for the first 2-3 days to push the first cooling front through the grain and to create uniform moisture conditions. Then run the fans during the coolest 9-12 hours per day for the next 3-5 days. This will push a second cooling front through the grain bulk. Aeration cooling generally only requires air-flow rates of 2-4 litres per second per tonne. Finally the grain requires approximately 50 hours of appropriate quality air each fortnight during storage. Use an aeration controller that will perform the cooling process at the right time and continue to aerate the grain selecting the coolest air to run fans. An effective aeration controller will also ensure fans don’t operate when the relative humidity is higher than 85 per cent, which can re-wet and damage grain if operated for extended periods.

Ineffective fumigation

Fumigation with phosphine is a common component of many integrated pest control strategies. Taking fumigation shortcuts may kill enough adult insects in grain so it passes delivery standards, but the repercussions of such practices are detrimental to the grains industry. Poor fumigation techniques fail to kill pests at all life cycle stages, so while some adults may die, grain will soon be reinfested again as soon as larvae and eggs develop. What’s worse, every time a poor fumigation is carried out, insects with some resistance survive, and pass the resistance gene into their progeny making control more difficult in the future.

Effective fumigation

Effective fumigation

Using the right type of storage is the first and most important step towards an effective fumigation. Only use fumigants, like phosphine, in a pressure-tested, sealed silo. Research shows that fumigating in a storage that is anything less than pressure sealed doesn’t achieve a high enough concentration of fumigant for a long enough period to kill pests at all life cycle stages. For effective phosphine fumigation, a minimum of 300 parts per million (ppm) gas concentration for seven days or 200ppm for 10 days is required. Fumigation trials in silos with small leaks demonstrated that phosphine levels are as low as 3ppm close to the leaks. The rest of the silo also suffers from reduced gas levels. Achieve effective fumigation by placing the correct phosphine rates (as directed on the label) onto a tray and hanging it in the top of a pressuretested, sealed silo or into a ground level application system if the silo is fitted with recirculation. After fumigation, ventilate grain for a minimum of one day with aeration fans running, or five days if no fans are fitted. A minimum withholding period of two days is required after ventilation before grain can be used for human consumption or stock feed. The total time needed for fumigating is 10-17 days. As a general rule, only keep a silo sealed while carrying out the fumigation (for example, one to two weeks). If grain moisture content is low (8-12%) the silo can remain sealed after fumigating but regular monitoring is essential to check for insect infestation and moisture migration to the head space.

Monitoring

When grain is put into storage it needs monitoring just like it does when it’s in the paddock – regularly. Check stored grain at least monthly, taking samples from the bottom, and if safe, the top of the storage.

Things to monitor:

- Insect pests

- Grain temperature

- Grain moisture content

- Grain quality and germination

Storage choices

When buying a new silo, buy a quality, sealable silo fitted with aeration and check with the manufacturer that it meets the Australian Standard for sealable silos (AS2628). Experience has shown that at least two sealable, aerated silos on farm provide the option for an effective fumigation and delivery program. Many older silos are not designed to be sealed and cannot be used for fumigation, however retrofitting aeration can reduce insect multiplication through grain cooling.

Seed held on farm (cereals — wheat, barley, oats)

Seed that is dry, cool and sound (not weather damaged) will remain viable for longer. In well-managed storage, germination percentages can be expected to reduce by only 5 per cent after six months. To achieve this, keep grain moisture content below 12%. Grain temperature also has a major impact on germination. Aim for grain temperatures of 20°C and below in seed storage by using aeration cooling (with auto control). Wheat at 12 per cent moisture content stored at 30-35°C (unaerated grain temperature) will reduce germination percentages and seedling vigour when stored over a long period. Position small seed silos in the shade or paint them reflective white to assist keeping grain cool. WA growers can treat seed with a grain protectant combined with a dyed grain fungicide in combination with aeration cooling to maximise insect control.

Pulse and oilseeds

Insect control options are limited for stored pulses and oilseeds. Aeration and phosphine fumigation are the main methods and controlled atmosphere (inert gasses such as carbon dioxide or nitrogen) may be an option. The effectiveness of phosphine fumigation on oilseeds is often reduced due to phosphine sorption during treatment. Monitoring gas concentrations with a gas monitor is essential to ensure the correct concentration is achieved for the correct length of time. Use sound grain hygiene in combination with aeration cooling to reduce insect activity. Small seed-size grains, such as canola, may need larger-capacity aeration fans to combat the greater amount of back pressure in the storage. Always store these grains at their recommended grain moisture content level.

Phosphine resistance is widespread – plan, monitor and control for clean grain

- Dispose of grain residues and seed gradings. Clean empty storages and grain handling equipment, including harvesters, field bins and augers.

- Sieve stored grain for the presence of insects at least monthly, or use pitfall traps. Also check grain temperature and moisture.

- If grain temperature has been kept below 15°C by aeration, live insect numbers are likely to be low.

- Sample grain three weeks before sale to allow time for any treatment.

- For effective fumigations, pressure test sealable silos at least once a year to identify any leaks and ensure rubber seals are maintained.

- Phosphine fumigation typically requires 7 to 10 days in a gastight sealed silo. When completed, open silo top with care, ventilate using aeration fan for one day; if not aerated, open silo top and ventilate for five days. The minimum withholding period is then two days after ventilation is completed. The total time needed for fumigation is therefore 10-17 days.

- Sieve a half-litre sample onto a white tray. Hold tray in sunlight to warm for 20 to 30 seconds to encourage insect movement.

- If live insects are found, identify them and fumigate in a gas-tight silo according to the label.

- Take care when climbing silos to sample grain for insects and wear a safety harness. Sample from the base, and if safe, take a sample from the surface of the grain.

Vigilant Monitoring Protects Grain Assets

When grain enters storage it needs monitoring, just as a crop does throughout the growing season.

Regular monitoring means problems are detected early and can be managed before significant grain damage occurs. It also avoids surprises at out-loading, prevents costly rejections from grain buyers and maintains your reputation for supplying quality grain.

KEY POINTS

- Regular monitoring allows early action to be taken if insects or grain quality issues arise.

- Failure to monitor grain not only increases the risk of damage and loss but can delay delivery if an issue is first identified at out-loading.

- Monitor grain temperature and moisture content and check for insect pests.

- Testing grain retained for seed after harvest helps plan for the following season.

Segregating grain

Monitoring starts at harvest — knowing grain condition and grade as it comes off the paddock determines the appropriate storage conditions.

- High-moisture grain requires drying or blending.

- Warm grain requires cooling.

- Variable quality grain will benefit from segregation.

When the grade is known (test at a registered receival site) ask what parameter(s) it’s close to for being downgraded or upgraded. It may be something that can be tested for and managed on farm, such as protein, screenings or test weight.

When the grade is known (test at a registered receival site) ask what parameter(s) it’s close to for being downgraded or upgraded. It may be something that can be tested for and managed on farm, such as protein, screenings or test weight.

Having this information on hand at harvest can support segregating grain as it comes off helping it to stay within the grade. Alternatively, blending grain from lower-grade areas of the paddock with that from higher grade areas may improve the overall grade.

In some cases, insect pests can come from machinery, so check grain on the way into storage so it can be treated or fumigated. Note: contact pesticides are not an option in Western Australia.

Monitor regularly

When in storage, grain is vulnerable to quality loss. Poor management can see grain come out of storage in an unsaleable condition. Monitor grain so problems can be addressed early before they cause significant damage. Dealing with an issue earlier rather than later is easier and more cost effective.

Check stored grain at least once a month during the cooler months and fortnightly during warmer months. Collect samples from the bottom of storage and, if safe, at the top.

In warm conditions (>30ºC) many grain pests can complete their life cycle in as little as 3–4 weeks causing significant damage.

When monitoring stored grain check:

- For insect pests

- Grain temperature

- Grain moisture content

- Grain quality and germination

Sampling stored grain

Collect samples from the areas where insects and mould are most likely to establish first. These areas are generally around openings — hatches, doors, aeration fan inlets, filling and emptying points.

The most common place for insects and mould in a silo is at the top, just below the surface of the peak of grain (see Figure 1). This is because it’s the last place aeration cooling or drying reaches, it’s exposed to the sun heating the headspace, condensation from the headspace and provides easy access for insects through the top lid, inspection hole or vents.

Always follow occupational health and safety guidelines and only climb to the top of a storage if it’s safe to do so.

Always collect samples from beneath the grain surface. At the bottom of a silo this means opening an outlet to run a small amount of grain out. A sampling probe is ideal for collecting grain from the top of a silo, but it’s often impractical or unsafe to climb up a silo with a sampling probe.

Checking for insects

Grain pests can be difficult to find because they are small, fast moving and some prefer the dark while others can be seen on the surface. There are numerous ways to detect them.

Tie the trap to something inside the storage so it doesn’t get lost or forgotten about before out-loading. Position the trap so a small amount is protruding out the top of the grain to capture insects crawling across the surface as well as those hiding beneath.

Temperature

Monitoring grain temperature is not only required to manage aeration, it can indicate potential mould or insect activity in the grain stack.

Insect activity generates heat, which provides favourable conditions for mould. When checking grain temperature, go beneath the surface, measuring in the same spot each time. Record test results to identify any temperature spikes, which will prompt further investigation.

Grain moisture

Grain moisture content influences mould and insect activity (see Figure 2). Identifying a change in moisture can reveal an issue before it causes significant damage. For example, an increase in grain moisture at the top of a storage could be a result of a leak, condensation or problem with aeration management.

Seed germination and vigour

Storing grain at the optimum temperature and moisture content as shown in Figure 2 not only reduces the risk of mould and insects, it maintains grain quality and germination.

CSIRO research reveals how moisture content and temperature affect the rate at which seed germination declines. A trial was carried out with premium quality wheat at 12 per cent moisture content and an initial seed viability of 100 per cent, stored for 150 days.

Storing at 20°C decreased the seed viability by only 1 per cent but storing at 30°C decreased viability by 21 per cent over the 150 days. Reduced germination rates result from a breakdown of grain cellular structure and function, with related changes in chemical composition and modification to enzyme and other bio-chemical systems.

Stored grain deteriorates with time under any conditions, but poor storage conditions (high grain temperature and moisture) accelerate the deterioration process markedly.

Testing germination rates on retained seed

If retaining grain for seed, a germination test and seed count test performed a month after harvest can help guide how much seed needs to be kept to achieve acceptable paddock plant populations.

If the germination test at this stage is poor, it might pay to buy in seed. If germination is satisfactory, use that to guide how much extra seed to keep, adding an allowance for all the other factors that will reduce germination and seed establishment.

Factors influencing how much seed needs to be retained for sowing include:

- Germination rate tested at harvest.

- Further decline in germination between harvest and sowing.

- Screenings, foreign and small seeds lost at cleaning.

- Allowance for seeds that germinate but don’t emerge.

- Seed weight (grams per 1000 seeds).

- Buffer to allow for change of plans in planting area.

Before sowing, carry out another germination test to check for decline in germination rates during storage.

CSIRO research shows this decline can be around 21 per cent if grain is not stored in ideal conditions. A decline of more than 10 per cent in germination rate from harvest to sowing should prompt action to improve the storage conditions or management in future years.

Grain temperature has one of the largest influences on seed germination and vigor. Monitor temperature regularly and ensure sound aeration management.