Grain aeration provides growers with a powerful tool to maintain grain quality during harvest and storage. Aeration cooling may not eliminate the need for chemical insect control, but it will dramatically slow insect development.

Key Points

- Grain temperatures below 20°C significantly reduce mould and insect development.

- Reducing grain temperature with aeration cooling protects seed viability.

- Controlling aeration cooling is a three-stage process — continual, rapid and then maintenance.

- Stop aeration if ambient, relative humidity exceeds 85 per cent.

- Automatic grain aeration controllers that select optimum fan run times provide the most reliable results.

Aeration cooling for pest control

While adult insects can still survive at low temperatures, most young storage pests stop developing at temperatures below 18–20°C (see Table 1).

At temperatures below 15°C the common rice weevil stops developing.

At low temperatures insect pest life cycles (egg, larvae, pupae and adult) are lengthened from the typical four weeks at warm temperatures (30-35°C) to 12-17 weeks at cooler temperatures (20-23°C).

An effective insulator

Without aeration, grain is an effective insulator and will maintain its warm harvest temperature for a long time.

Like housing insulation, grain holds many tiny pockets of air within a stack — 100 tonnes of barley requires a silo with a volume of about 130 cubic metres, 80m3 is taken up by grain and the remaining 50m3 (38 per cent) is air space around each grain.

Seed viability

Research trials reveal that wheat at 12 per cent moisture content stored for six months at 30-35°C (unaerated grain temperature) will have reduced germination percentage and seedling vigour.

Aeration cooling

Aeration cooling can be achieved with air-flow rates of 2–3 litres per second per tonne delivered from fans driven by a 0.37 kilowatt (0.5 horsepower) electric motor for silos around 100t.

Research carried out by the Department of Agriculture, Fisheries and Forestry (DAFF), Queensland shows that with the support of an aeration controller, aeration can rapidly reduce stored grain temperatures to a level that helps maintain grain quality and inhibits insect development.

During trials where grain was harvested at 30°C and 15.5 per cent moisture, grain temperatures rose to 40°C within hours of being put into storage.

An aeration controller was used to rapidly cool grain to 20°C and then hold the grain between 17–24°C during November through to March.

Before replicating similar results on farm, growers need to:

- Know the capacity of their existing aeration system.

- Determine whether grain requires drying before cooling can be carried out.

- Understand the effects of relative humidity and temperature when aerating stored grain.

- Determine the target conditions for the stored grain.

Air used for cooling grain

Varying ambient conditions affect stored grain differently depending on the combination of temperature and relative humidity outside the silo and the temperature and moisture content of the stored grain (see Table 2).

Grain with a higher moisture content can be cooled quickly with low-humidity air due to the evaporative cooling effect that occurs inside the storage.

The relative humidity of the ambient air affects the efficiency of grain cooling.

In an ideal world we would select air for cooling that is low in temperature and relative humidity, but these conditions rarely occur.

Air movement within the stack

Grain at the top of the stack is the hottest, as heat rises through the grain and it is exposed to the head space in the silo (see Figure 1).

As the air in the head space heats and cools each day, it creates ideal conditions for condensation to form and wet the grain on the top of the stack.

Be aware aeration drying requires specifically-designed equipment and the process is much slower than aeration cooling or hot-air drying.

The cooling process

Operating an aeration fan for cooling requires a planned control program, which is best done with an automatic aeration controller.

But even without an aeration controller growers need to aim for the same run time, following the same process.

Without aeration, grain typically increases in temperature immediately after it enters the storage.

The initial aim is to get maximum air-flow through the grain bulk as soon as it enters storage, to stop it from sweating and heating.

When first loading grain into storage, run the aeration fans continuously from the time the grain covers the aeration ducts for the next 1-3 days, until the cooling front reaches the top of the storage.

However, do not operate the aeration fans on continuous mode if the ambient relative humidity is higher than 85 per cent for extended periods of time as this will wet the grain.

After the aeration fans have been running continuously for 2–3 days to flush out any warm, humid air, reduce run time to 9–12 hours per day during the coolest period, for the next seven days.

The goal is to quickly reduce the grain temperature from the mid 30s°C down to the low 20s°C.

An initial reduction in grain temperature of 10°C ensures grain is less prone to damage and insect attack, while further cooling becomes a more precise task. During this final stage, automated aeration controllers generally run fans during the coolest periods of the day, averaging 100 hours per month.

Grain temperature is gradually reduced as low as possible and then maintained throughout the storage period.

The risks of getting it wrong

Running aeration fans on timers that are pre-set for the same time each day will not ensure the selection of the most appropriate air for grain quality maintenance.

The biggest risk with running aeration fans without a controller is forgetting or not being available to turn fans off if the relative humidity exceeds 85 per cent.

Operating fans for extended periods of a few hours or days in humid conditions can increase grain moisture and cause moulding.

Aeration controllers are designed to automatically select the best time to run aeration fans. Fans on these systems only run when the conditions will benefit the stored grain.

Cooling or drying — making a choice

Knowing whether grain needs to be dried or cooled can be confusing but there are some simple rules of thumb.

For longer-term storage grain must be lowered to the correct moisture content.

Grain that is dry enough to meet specifications for sale (12.5 per cent for wheat or 13.5 per cent for sorghum) can be cooled, without drying, to slow insect development and maintain quality.

Grain of moderate moisture (up to 15 per cent for wheat and sorghum)

can be either cooled for short periods to slow mould and insect development or, dried providing the right equipment and conditions are available.

After drying to the required moisture content, grain can be cooled to maintain quality.

High-moisture grain (for example, 16 per cent or more for wheat and sorghum) will require immediate moisture reduction before cooling for maintenance.

Installation and maintenance tips

When retrofitting an aeration system, avoid splitting air-flow from one fan to more than one storage. Each storage will provide

a different amount of back-pressure on the fan resulting in uneven air-flow and inefficient or even ineffective cooling.

If buying an aeration controller be aware that most controllers need to be installed by an electrician.

The preferred mounting location for aeration controllers is outside where the sensors can get ambient condition readings but are sheltered from the direct elements of the weather.

To avoid the chance of a dust explosion, avoid installing aeration controllers in a confined space.

Ensure your electrician installs wiring properly insulated and protected from potentially-damaging equipment, such as augers.

Monitoring a must

Aeration controllers reduce the amount of time operators need to physically monitor grain storages and turn fans on and off, but units and storage facilities still need to be checked regularly.

Most controllers have hour meters fitted so run times can be checked to ensure they are within range of the expected total average hours per month.

Check fans to ensure they are connected and operating correctly.

The smell of the air leaving the storage is one of the most reliable indicators if the system is working or not.

The exhausted air should change from a humid, warm smell to a fresh smell after the initial cooling front has passed through the grain.

Animals can damage power leads and automatic controller sensors and fan blades or bearings can fail, so check these components regularly.

Check for suction in and feel for air-flow out of the storage vents when the fans are running.

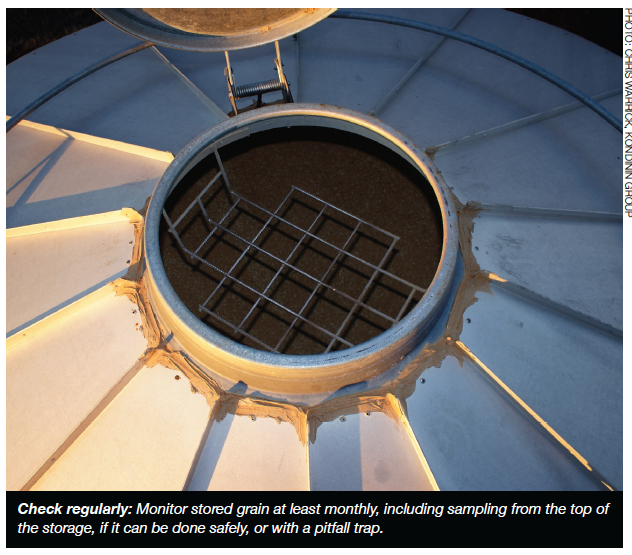

Keeping grain at the right moisture and temperature levels will reduce the likelihood of insect infestations, but stored grain still needs to be sampled regularly and monitored for any changes.

If possible, safely check the moisture and temperature of the grain at the bottom and top of the stack regularly.