Insect resistance testing

Contact details to send grain storage insect samples for resistance testing.

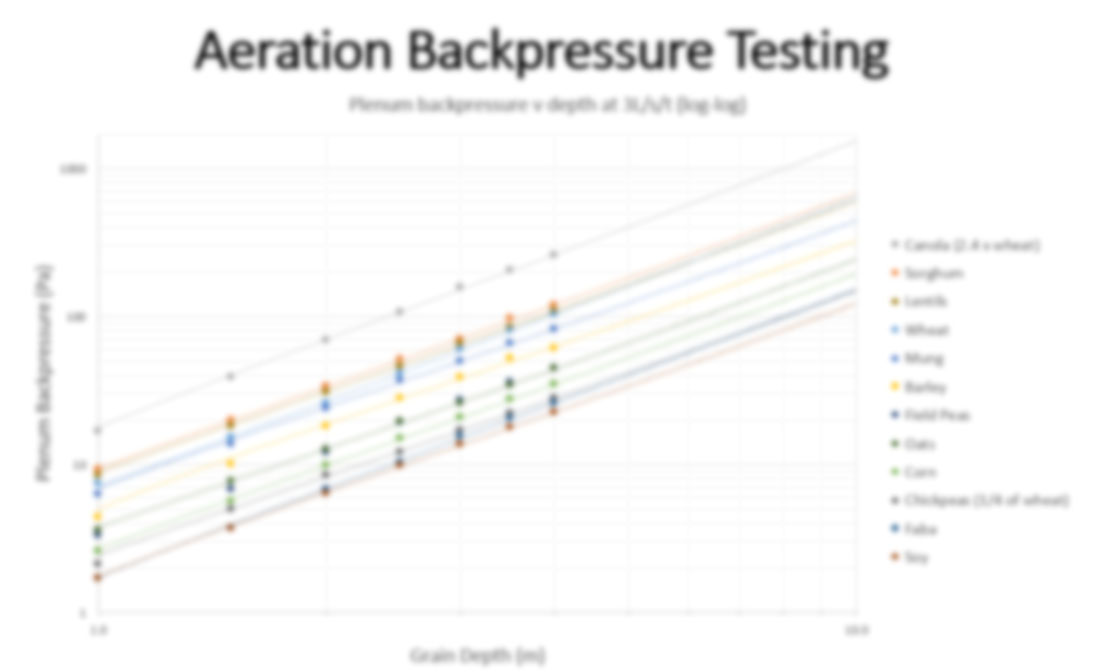

Continue readingAeration backpressure test results

Test results from recent aeration backpressure testing of various grain types, at a range of depths and air-flow rates.

Continue readingAeration cooling can help save moist grain

With substantial yields expected across much of the Australian grain growing area and wet weather hampering harvesting efforts, growers are being encouraged to consider how they will manage on-farm storage to preserve grain quality.

Storing cereals and pulses with an average moisture content above 12.5 per cent can cause a range of issues, including mould and insect outbreaks in storage facilities.

Grains Research and Development Corporation (GRDC) National Grain Storage Extension Project Coordinator Chris Warrick said aeration cooling could play a critical role in successful on-farm storage this season.

“Aeration cooling allows grain that was harvested slightly over moisture to be stored for up to three to four weeks before it is dried or blended with dry loads,” he said.

Recent survey data has revealed that aeration cooling is widely underutilised in Australian on-farm grain storage, with two thirds of growers not using it, not realising it can be retro-fitted to their existing silos, or not ordering it as part of new storage capacity.

Mixing over-moist grain with drier loads will lead to a lower average moisture once the two loads are properly blended.

“Ideally, the blended load will be put back into storage with aeration cooling to help redistribute moisture evenly among the grain,” Mr Warrick said.

“The cooling fans need to be run continuously if the grain has a moisture content above 12.5 per cent, unless the ambient relative humidity is above 85 per cent for an extended period. Even air-distribution through the silo and open lids or vents are essential, as is monitoring the grain-temperature daily.

“The fans must deliver at least two litres of air per second per tonne of grain (l/s/t) just to hold over-moist grain safely.

“Drying grain out requires much higher airflows, in excess of 15 litres of air per second per tonne, which is only possible with high capacity systems specifically designed for aeration drying.”

Grain drying facilities have the benefit of being able to dry grain down to a safe moisture content for storage but are different systems to aeration cooling, which is important to understand.

Aeration cooling can enable over moisture grain to be held temporarily until it can be dried or blended. The longer-term benefits of aeration cooling are preserving grain quality including germination characteristics, grain colour in pulses and creating unwelcoming conditions for mould and insects.

Mr Warrick said the most common cooling mistake was not running the fans for enough hours to thoroughly cool the entire silo and push fresh cooling air right through the store. This could result in grain at the top of the silo remaining warm.

Grain that has been harvested, dried or blended below 12.5 per cent moisture content can be managed with a three-step cooling process.

- Cooling fans should be run continuously from as soon as the aeration ducts are covered until three to five days after the silo is filled, or until the air coming out the top of the silo smells clean and fresh.

- They should then be run for the 12 coolest hours of the next five to seven days.

- And then for the 100 coolest hours of each subsequent month. To optimise this process an automated aeration controller is recommended.

Aeration Cooling

Grain storage specialist Chris Warrick presents a webinar on aeration cooling

Continue readingAeration Drying – Measuring airflow

Grain storage facilities: Planning for Efficiency and Quality

A Grains Industry Guide

Overview and introduction

Grain storage systems come in a range of shapes and sizes to meet farm requirements and careful planning is needed to optimise an on-farm grain storage facility investment. According to the option selected, on-farm grain storage systems can provide a short-term or long-term storage facility. Depending on the goal of on-farm storage, whether it be access to improved markets or simply to maximise harvest efficiency, there are a number of options available.

Grain storage systems come in a range of shapes and sizes to meet farm requirements and careful planning is needed to optimise an on-farm grain storage facility investment. According to the option selected, on-farm grain storage systems can provide a short-term or long-term storage facility. Depending on the goal of on-farm storage, whether it be access to improved markets or simply to maximise harvest efficiency, there are a number of options available.

Harvest is the ideal time to plan future grain storage system requirements, as it can help identify issues and opportunities for future harvest operations that may otherwise be forgotten once next year’s crop cycle gets underway. Costs and storage flexibility can vary between grain storage options as can longevity of the investment. Table 1 identifies the major on-farm grain storage options, their advantages and disadvantages.

Silos are the most common method of storing grain in Australia, constituting 79% of all on-farm grain storage facilities nationally (see Figure 1).

Silos come in a variety of configurations, including flat-bottom or cone base, and both are available as gas-tight sealable or non-sealed, aerated and non-aerated. The balance of on-farm grain storage facilities can be split between grain storage bags (9 per cent) and bunkers or sheds (12 per cent). Grain-storage bags are increasing in popularity as a short-term storage solution to assist harvest logistics. With careful management growers can also use silo bags to provide short-term marketing opportunities. For similar storage time-frames to grain storage bags, and where options are limited, growers can also use sheds to temporarily store grain during harvest — provided they have been well prepared.

Superior silo: The dominant on-farm grain storage option is the silo in either a flat-bottom or cone-base configuration.

Superior silo: The dominant on-farm grain storage option is the silo in either a flat-bottom or cone-base configuration.

Benefits and pitfalls of various storage types

Silos: fumigation options

A gas-tight sealable silo will ensure phosphine, or other fumigants and controlled atmospheres, are maintained at a sufficient concentration to kill insects through their complete life cycle of eggs, larvae, pupae and adult. Be aware of cunning marketing terminology such as ‘fumigatable silos’. Although such a silo might be capable of sealing with modifications, a gas-tight sealable silo needs to be tested onsite to meet Australian Standard (AS 2628-2010) after installation. Gas-tight sealable silos also can be used for alternative methods of insect control including controlled atmospheres of inert gasses, such as carbon dioxide or nitrogen. Current costs of using these gases (between $5 and $12/tonne to treat stored grain compared with $0.30 per tonne using phosphine) carbon dioxide and nitrogen atmospheres will arguably be used solely by niche growers, such as organic growers, until gas is less expensive.

There is significant work being carried out in lower-cost nitrogen gas generation and if buying a silo, ensure it is gas-tight for future proofing of the investment.

Silos: sizes and construction

Silos can be transported fully constructed and ready to stand, or can be built onsite. While intra-state variations apply, transportable silos are typically limited to 140 tonnes capacity due to road transport regulation limitations. Most smaller, 50–70t, cone-bottom silos are prefabricated and transported. Cone-bottom silos are easier to clean than flat-bottom silos due to their self-emptying design, but are limited to capacities less than 300t. Some growers require gas-tight storage facilities of greater capacity and increasing silo capacity requires quality materials and design. Silos can be built onsite and are available in sizes up to 3000t. The increased surface area of a larger silo requires more sheet metal joins, providing more opportunity for gas to escape.

Silos: lifespan

Silo lifespan is another advantage delivered through investment in gas-tight sealable silo storage infrastructure. A well-built, aerated, quality gas-tight sealable silo constructed to meet the Australian standard (AS 2628-2010) with a thorough maintenance regime could be expected to provide around 25 years of serviceable life before major repairs may be required. Silos: aeration While some preliminary research has been carried out using other grain-storage methods, silos permit simple administration of aeration after harvest to cool grain.

Aeration cooling of grain in-storage creates uniform moisture conditions and slows or stops insect pest life cycles.

Depending on the temperature reductions achieved; this can deliver significantly-reduced insect numbers.

For older, unsealed silos, consider retro-fitting aeration as the first option. Aeration cooling requires airflows of at least 2-3 litres of air, per second, per tonne. For example, a 100t silo will require 200-300 litres per second (l/s) of air to cool the grain effectively. Aeration fans also require well-designed perforated ducts or a plenum to assist in dispersing airflow evenly throughout the silo. Selecting the coolest air for the grain is best done using an aeration controller, but aeration fans should be run continuously for at least three days for smaller silos (less than 100t) and up to a week for large silos (over 100t) as soon as grain covers the aeration ducting. This initial process removes the harvest heat and equalises grain moisture. After initial harvest heat has been removed, the controller can be switched on to continue the cooling process.

For older, unsealed silos, consider retro-fitting aeration as the first option. Aeration cooling requires airflows of at least 2-3 litres of air, per second, per tonne. For example, a 100t silo will require 200-300 litres per second (l/s) of air to cool the grain effectively. Aeration fans also require well-designed perforated ducts or a plenum to assist in dispersing airflow evenly throughout the silo. Selecting the coolest air for the grain is best done using an aeration controller, but aeration fans should be run continuously for at least three days for smaller silos (less than 100t) and up to a week for large silos (over 100t) as soon as grain covers the aeration ducting. This initial process removes the harvest heat and equalises grain moisture. After initial harvest heat has been removed, the controller can be switched on to continue the cooling process.

Silos: aeration drying

Specific drying silos are designed to maximise drying efficacy and have minimum air-flow rates of between 15–20 litres per second per tonne (l/s/t) of storage. Specially-designed drying silos often have a truncated, or secondary, base cone to assist in the efficiency and efficacy of drying stored grain. Drying with ambient air requires a relative humidity well below that of the equilibrium relative humidity of the grain. Drying silos often allow the addition of heat at the air intake to improve the moisture removal capacity of the air flowing through the grain.

Specific drying silos are designed to maximise drying efficacy and have minimum air-flow rates of between 15–20 litres per second per tonne (l/s/t) of storage. Specially-designed drying silos often have a truncated, or secondary, base cone to assist in the efficiency and efficacy of drying stored grain. Drying with ambient air requires a relative humidity well below that of the equilibrium relative humidity of the grain. Drying silos often allow the addition of heat at the air intake to improve the moisture removal capacity of the air flowing through the grain.

Silos: capital investment

As a permanent infrastructure fixture on a farm, silos are initially one of the most expensive options of grain storage at around $100 to $140/tonne for transportable sealed silos. To this can be added foundation requirements, which can vary between $2500 for a 70t transportable silo to considerably more for a flat-bottom silo with aeration ducting incorporated into the floor. Larger silos built onsite typically have an outlay cost of about $80 per tonne of stored grain. But looking at this investment over the life of the storage can see this figure drop significantly to being one of the cheapest forms of on-farm grain storage.

Silos: safety

Working at heights can be dangerous without the appropriate safety precautions. In the case of silos, this can mean working up to 16m off the ground. A climb to the top is required for regular inspection through the top hatch if grain is stored for more than a month. Silo designs now incorporate ground-operated lids, caged ladders, platforms and top rails to minimise the risk of operators falling. Facilities for harness attachments, which should be worn by all operators climbing silos, are also fitted.

Working at heights can be dangerous without the appropriate safety precautions. In the case of silos, this can mean working up to 16m off the ground. A climb to the top is required for regular inspection through the top hatch if grain is stored for more than a month. Silo designs now incorporate ground-operated lids, caged ladders, platforms and top rails to minimise the risk of operators falling. Facilities for harness attachments, which should be worn by all operators climbing silos, are also fitted.

Silos: retro-sealing

To meet the requirements of fumigation and utilising existing silo infrastructure, some growers have invested in retro-sealing older silos. In most instances these silos are high capacity (> 500t), flat-bottomed silos. Retro-sealing specialists use an array of rubber, specialised rubberised cements and silicon compounds to seal sheet joins, bolts, rivets, lids and openings on older silos. These are typically sprayed on with an air-operated gun with coarse flows to handle the heavy product viscosity.

[box]The interface between the pad and the bottom sheet of the silo and the top sheet meeting the roof should be given special attention as they are commonly points of limited seal integrity. Customised sealing plates can also be fabricated for doors, vents and openings. Oil-filled pressure-relief valves will also be fitted. The cost of retro-sealing an older style silo can be significant, often totalling as much as 50 per cent of the cost of a new sealed unit. Ensure the retro-seal contractor includes a guarantee that when completed the silo will meet the Australian Standard for sealed silos AS2628. After sealing, consider ongoing maintenance costs. Check coating integrity annually and patch as required to maintain an effective seal. Particular vigilance is needed around the storage base, and where the walls meet the lid, as expansion and contraction of the metal can damage the retro-seal finish.[/box]

Silo buyers’ checklist

- Aerated, gas-tight sealable silos should always be the preferred option.

- Ask the manufacturer to provide a guaranteed pressure test in accordance with AS2628-2010 on-site after construction or delivery. Pressure testing a storage when full of grain is also important.

- Ensure a pressure relief valve capable of handling the maximum air-flow in and out of the silo due to ambient temperature variations is fitted.

- A silo aeration fan can be used with care to pressurise a sealable silo to carry out the annual pressure test for leaks.A tyre valve or a larger fitting may also be installed to determine the volume of air required for the test.

- Seal mechanisms on inlets and outlets should be simple to operate and provide even seal pressure.

- Seal rubbers should be quality high-density EPDM (ethylene-propylene-diene-monomer) rubber, maintain a strong memory and be UV resistant.

- Look for ground-operated lids that provide an even seal on the silo inlet.High-quality ground-opening lids will provide a gas-tight seal, but some will still require a climb to the top of the silo to lock down the lid for fumigation.

- Aeration cooling fans are a must-have accessory for a new silo and provide significant benefits for stored grain.Buy these with the silo or as an aftermarket accessory and specify airflow rates of at least 2–3l/s for every tonne of grain storage capacity of the silo.

- Aeration drying silos are an option, but are typically shaped to maximise drying efficiency.Drying fans need to deliver between 15 and 20l/s for every tonne of grain storage capacity of the silo and additional sealable venting in the roof should be fitted.

- Outlet access for unloading should be simple to operate and permit ample auger access.

- Look for a sturdy base and frame on elevated cone base silos with quality weldments. Galvanised tubing has a heavier coating than galvanised rolled hollow section (RHS) but is more difficult to shape and weld joins.

- Ensure wall sections incorporate a positive seal between sheets and sealed riveting where rivets are exposed.

- Always consider access and safety features, including roof rails, ladder lockouts, platforms and ladder cages. It can be argued that a ladder should always be fitted, as inspection of the grain in the top of the silo should be carried out regularly.

- A quality outside finish will provide a superior life. White paint reduces heating of grain in storage. It comes at a cost premium but is superior to zincalume finishes over time.

- A chalk-board patch painted on the silo base can be useful for recording grain and treatment details, including variety, protein and moisture content, fill date and fumigation details.

- Check silo design inside and outside for ease of cleaning. Check walls and aeration ducting including the floor for grain trap points.

- Consider grain segregation requirements when determining silo size. Smaller silos allow better segregation.

- Ensure adequate venting is fitted to the roof of silos with aeration fans to permit adequate air-flow without restriction. These vents should be easy to clean. Check seals and lock down if it is a sealable silo.

Grain-storage bags

As a relatively new on-farm grain storage option, silo bags have been widely used in Australia since the early 2000s, although they have been used overseas for much longer. As with most things new, numerous disasters, mostly due to operator error and lack of inspection vigilance, have earned grain bags a bad name. They can provide useful short-term storage (less than three months) and a logistics management tool during harvest. They must be installed on a well-prepared site away from bird habitats, including trees and water sources.

Grain-storage bags: capacity

Typical storage capacity is around 240 tonnes, but other sizes including 200t and 150t bags are also available.

Take care when buying bags. Quality of bag materials varies and using bags for grain storage that have been designed for silage storage is not recommended.

Grain-storage bags: using them successfully

Successful use of grain bags as an on-farm grain storage option requires a carefully-prepared pad. Anecdotally, an elevated, well-drained pad provides optimal results where no stubble (which can harbour vermin) or rocks can tear the grain storage bags as they are being filled and unloaded.

Fill rates are typically 3–4 tonnes per minute. Always fill bags up-the-slope and ensure brake settings on the filler are set to ensure the appropriate stretch of the bag is achieved. While typically a 10 per cent stretch, this can be adjusted down for hot weather conditions or up for cool ambient weather. When full, regularly and vigilantly check the bags for cuts, nicks and holes and patch these with silicon or bag sticky tape available from the bag supplier.

Grain-storage bags: costs

The two pieces of equipment required for loading and unloading grain storage bags can cost around $27,000 each. This equipment can be hired, although having your own can reduce the pressure of having to get grain in and out of the bags within a specified timeframe as demand for this hire equipment is high at the peak of harvest. The bags themselves are single-use and cost around $5 per tonne stored, or $1000 plus for a 240t bag. Consider site-preparation, including any earthworks and fencing requirements, time and labour costs for maintenance when calculating the comparative costs of using grain bags.

Grain-storage bags: useable lifespan

Grain-storage bags are best used for short-term storage only. While longer-term storages are possible, three months is regarded as a maximum storage period. Beyond this, there is considerable risk of grain losses and spoilage in many of Australia’s grain production regions.

Grain-storage bags: pest and insect control

Fumigation with phosphine in bags has been recently proven in Australia as an option if the correct method of application and venting is followed. Alternatively, fumigation of grain-storage bags can also be performed using gases like ProFume. But this is only available for use by licensed fumigators and the cost is generally considerably higher than phosphine. In addition to insects, vermin including mice and birds can attack grain bags. Outside baiting, reducing habitat provision and food sources (including regular checking and patching of bags where required) is the best way to reduce vermin risk. Grain storage bags: access One often-overlooked aspect of using grain-storage bags in the paddock is their accessibility after harvest. Unless the bags are placed on, or near, an all-weather access road, they can be difficult to unload if wet weather conditions prevail post-harvest. The pad site needs to be large enough for trucks and machinery for bag unloading and allow access in wet conditions.

Sheds and bunkers

Bunkers are commonly used by bulk handling companies, but require careful site preparation, labour for handling large tarp covers and machinery to move grain on and off the grain stack. Effective treatment of insect infestation is difficult in sheds and bunkers. For on-farm storage, grain bags may be a more suitable short-term alternative. Sheds can provide dual-purpose functionality for storage of other products including fertiliser and machinery. But the risk of grain contamination requires a focus on impeccable hygiene practices. As a permanent infrastructure investment, sheds can be continually used and have a retained value on-farm with a service life expected to exceed 30 years.

Specialist grain-storage sheds can be constructed to make filling and unloading simpler. Aeration and sealing methods for fumigations are best considered in the early shed design phase.

Sheds are most useful as a short-term storage solution to assist harvest logistics. They can be a useful component of an on-farm grain storage system that incorporates other gas-tight sealable grain storage facilities

Sheds: costs

Cost of grain storage in sheds varies widely depending on footing and slab requirements as determined by soil type. Method of construction and alternative uses can also vary the cost of construction. Sheds: aeration Aerating grain stored in a shed is difficult due to the open design of most shed structures. But customised ducting and air manifolds can be designed by grain aeration specialists to aerate grain stacked in a shed.

Sheds: pest and insect control

Given the open nature of most sheds on-farm, pest and insect control presents some challenges. Fumigation with gas-proof sheeting placed over the stack is difficult. Bulk handlers, including CBH in Western Australia, have invested heavily in sealing gas-tight bulk storage sheds to permit fumigation. On-farm, sheds are also prone to spoilage by mice and birds.

Sheds: loading and unloading

One of the biggest drawbacks of sheds used for grain storage is the ease of getting grain in and out. Using an auger or belt conveyor to fill the shed from the truck is common practice. For out-loading, some operators opt for bulk-handling buckets on front-end-loaders or tele-handlers to fill direct into trucks. Some grain trade operators use this approach to minimised grain damage when handling grains prone to splitting, such as lentils. Sump load points are occasionally used, with a lowered section of the floor utilising gravity to assist in sweeping grain into a loading point. Grain vacuums can also be used to out-load grain from sheds. Regardless of the out-loading options, inevitably, a final clean is performed with a broom and grain shovel, which can take time if hygiene is to be maintained.

On-farm grain storage facility considerations

Depending on budget and expectations, investing in and planning a grain-storage facility requires a range of considerations, regardless of the storage type.

Access for in-loading and out-loading

Continuous loop roads around the grain-storage facility requiring minimal, or no, reversing are ideal and can dramatically improve loading and out-loading rates as well as minimising damage to equipment through accidental collision. Dedicate an ample-sized pad to permit auger or grain conveyor access and ease of shifting grain loads. Where steeper slopes exist, some growers have terraced the slope with a retaining wall, to allow them to reduce the lift height (and auger size) for loading the silo. Where retaining walls exceed 1m in height, consider guard rails and access steps.

Proximity to resources (power sources — electricity and fuel)

Whether the facility is to be powered for aeration, i.e. using petrol or electricity, consider the proximity to these resources, particularly if the facility will be built in stages as each stage becomes affordable. Connection to mains power can be expensive depending on the distance to the line. Some large drying fans also require three-phase power which requires a specific pole transformer.

With augers, machinery and tipping trucks in use around the facility, placing power underground is expensive, but can significantly improve safety.

It is worth considering fuel sources and fuel lines for dryer installations, or future dryer installations, when planning the facility layout and constructing the pad.

Health and safety considerations

Operational safety considerations should be key to the facility design. Allow plenty of space for auger transport and movement around the facility.Ensure overhead power-lines are located nowhere near the pad where augers, conveyors or trucks might be operating — ideally locate power underground.

Pads should be flat, hard-packed stands that allow tipping trucks to elevate without risk of toppling over sideways.

Minimise any slopes and ensure they are of a constant grade. Position drainage lines and holes away from high-traffic areas to reduce the risk of equipment falling through while maximising drainage effectiveness. Electrical switch boards should incorporate residual current devices (RCDs) to prevent electrical shock if, for example, an electrical cable was accidentally cut. A qualified technician is required to carry out any 240-volt electrical work. They will ensure the components are safe to use in areas where combustible dusts are present.

Road access

The ability to get trucks in and around the grain-storage facility is paramount to its success. Sealed or hard, all-weather roads to the site from a main road are essential for year-round out-loading, which will ensure grain sale contracts are met in a timely manner and can deliver marketing advantages. Proximity to trees and insect or bird havens Avoid locating storage facilities near trees, haystacks and haysheds. All are havens for insects and birds, making migration from nature to the grain stored in the facility easier. Similarly, water sources are attractions for vermin and birds. Avoid water sources when selecting a site for a grain storage facility.

Proximity to harvest locations

One of the most important considerations of facility placement and layout is harvest logistics. While placing silos close to a house or existing infrastructure is most common, it may not be the most efficient placement from a logistics perspective. More often than not, storage facilities are located according to proximity to power and facilities, so a balance between ease of accessing services and optimising harvest logistics has to be struck.

Determining storage capacity requirements

Calculating ‘adequate storage capacity’ can involve an enormous range of variables. Consider what would be the ’ultimate‘ in on-farm storage capacity for the farm and then plan a series of stages to achieve this ultimate goal. For some growers, ultimate storage capacity is 100 per cent of their harvest, while others will always use an external bulk handling system to some extent. This is likely to vary between State bulk handling operators, dominant crop types, target markets and distance from the farm to bulk handlers. As an initial step, aim for a reasonable proportion of the total harvest and plan to expand the facility from there. Consider investing in a number of small silos as the first step and buy larger silos as the business expands. Smaller silos, for example around 70 to 100 tonnes, will always be valuable for segregation and blending or insect control in small parcels of grain. Fumigating a small amount of grain in a large silo can be expensive because treatment is based on silo volume, not grain volume.

Determining out-loading throughput rates

A standard out-loading rate is around 3-4 tonnes per minute and anything exceeding that will enable the driver to get back on the road to their delivery port quicker.

Weighbridges

With fines for overloading increasing in severity and occurrence in most States, using a weighbridge could pay for itself quickly. Weighbridges can be incorporated into the silo load-and-unload loop with effective installations providing readouts for the driver when approaching from both sides. A weighbridge, fully installed will add a cost of about $130,000 to the facility.

Blending abilities

The ability to blend grains and optimise specifications is one of the primary benefits of an on-farm storage facility. The ease of out-loading for blending is greatly improved by adding a belt or drag-chain grain conveyor and elevator system to the facility. Grain can be simultaneously out-loaded from multiple silos and loaded into another. The alternative is to blend into a truck and then auger back, which can be fiddly but effective if small batches are blended occasionally.

Sampling abilities

Keeping a record and sample of grain stored on-farm can be useful for subsequent testing and quality assurance. Owners of larger on-farm, grain-storage facilities commonly add a sampling shed where grain-quality specifications are collected and stored. Taking the sample from silos can be easier if sealed silo ports for sample collection can be easily accessed to obtain a cross section of the stored product. Truck sampling options include push spears and vacuum spears, which are designed to take a profile section of the load. They are used by many growers and are easier to operate from an elevated platform. If adding an elevated platform to the facility, remember to add handrails to minimise the risk of falling.

Cleaning and facility maintenance

Maintaining good site hygiene is easier with a quality hard surface. Concrete pads are essential for silos to sit on but extended aprons can also assist cleaning spilt grain from loading and unloading.

Common grain trap points include dump-pits, drainage or aeration channels and around silo bases.

Clean all grain off the site on a regular basis to avoid harbouring insects, which may infest stored grain. Ensure a water point is accessible for washing out silos after they are emptied. Grain vacuums are popular with owners of flat-bottomed silos to remove residual grain where sweep augers have not been able to reach.

Facility earthworks

When determining the requirement for earthworks, always allow a buffer around the pad for construction-vehicle movement. Raised pads are most common as they minimise the potential for water damage to the facility and stored grain. The height of the pad will typically vary according to the overall topography of the site relative to the landscape but 500mm above average topographic level is not uncommon.

Soil type impacts

Soil type can have a huge bearing on silo foundation thickness and requirements for facility earthworks. Foundations are normally engineered with depth of footing and reinforcing is determined according to the physical properties of the soil. Highly-reactive soils shrink and swell according to their level of moisture and typically require additional foundation engineering and reinforcing, which comes at a greater cost. As a rule of thumb, experienced silo-pad concreters assume soil type according to region for quoting purposes with slight variations dependent upon on-site requirements.

Drainage

In addition to maintaining a raised, firm pad for the storage facility, plan for drainage to handle and direct run-off away from the pad. In some cases the natural topography of the site may assist free drainage while on flat sites, drainage channels may have to be formed to carry water away from the site. A well-designed pad for transportable cone-bottom silos will ensure water does not pool near the base structure, which can quickly rust out.

Lighting

Loading and out-loading is often carried out at night during harvest and effective lighting not only makes the job easier for drivers but also improves safety at the site. Efficient and robust forms of lighting, including LED, are suitable choices for short-throw requirements. If laying electrical cables underground, for aeration or auger drives, consider laying electrical cables for lighting at the same time.

Loading and out-loading is often carried out at night during harvest and effective lighting not only makes the job easier for drivers but also improves safety at the site. Efficient and robust forms of lighting, including LED, are suitable choices for short-throw requirements. If laying electrical cables underground, for aeration or auger drives, consider laying electrical cables for lighting at the same time.

Communications

With numerous market opportunities and volumes of information and data detailing specifications of stored grain increasing, facilities for data transfer and communication add value to any site plan, particularly if the site is to be equipped with a sampling and testing shed.

Planning to expand

It is rare any grower would set out to build a complete on-farm grain storage system from scratch. The capital requirement would be enormous and in most cases grain storage facilities grow with increasing farm productivity. The careful planning of a facility to be built in stages can ensure design aspects of the larger site are not overlooked when constructing these stages. It can also lead to savings through coordinated placement of pipes, electricals and concrete pads. Expansion is most commonly, and simplistically, an extension of a single line of silos, although variations include circles with a central receival and out-loading point. Single lines of silos offer the ability to run a single out-loading belt, which can feed grain into an elevator for out-loading or transfer to other silos.

When planning to expand, consider drying options including the ability to undertake batch drying or dedicated drying silos with ample airflow rates.

Also plan for aeration controller placement and associated electricals.

Staking out the facility

Everything can look good on plans, but it is important to physically stake out the site of grain facilities to ensure proportions have not been underestimated or overlooked. Driving pegs onto the site to indicate silo placement, pad borders and the positioning of roads and weighbridges can help visualise the suitability of the plan for the site.

Adapting existing facilities

In many cases, existing facilities are worked into the design to use existing infrastructure.Upgrading, including retro-sealing silos and sheds, can be an option to reduce the overall cost of storage per tonne, but remember to include ongoing maintenance costs for retro-sealed facilities. Offset placement of silos in lines parallel to lines of existing silos can be an option and can offer out-loading efficiencies. Apart from fitting in around older storages, the first modification to older silos should be the installation of an appropriately sized aeration fan and ducting.

On-site office and sampling sheds

An on-site office is ideal for keeping records and samples of stored grain. It can house expensive, sensitive testing equipment and be used as a crib-room for drivers and employees. Portable site offices are a common choice as they can be fitted with air-conditioning and are often pre-wired for electrical outlets. Used site offices regularly come up for sale on mining sites and can be bought at a fraction of the new price. As a minimal alternative, an on-site cabinet for load documentation and records will ensure hard copies of silo contents and load specification details are kept on site.

Dump pits

Dump pits can be installed in combination with paddle or drag conveyors to quickly and easily take and elevate grain to load silos.

Carefully cover dump pits when not in use to keep water out and keep pits and surrounding areas clean to minimise contamination and spoilt grain.

Conveyor types

Numerous options for shifting grain around the site are available and each has benefits and disadvantages. Maximum angles of elevation vary between conveyors according to grain but figures are usually quoted for wheat. Augers are most common due to their portability and are one of the cheapest methods of elevating grain into a number of silos. Elevation angle and flight turn speed have a bearing on flow rates with higher elevation angles reducing throughput and impacting on hygiene. Hygiene can be compromised with lower throughput, as grain tends to sit between the auger flights. It is best removed by reversing the auger until all grain has been cleared.

Augers can occasionally damage split-prone grain — particularly old augers with worn flighting. Belted conveyors are the second most-commonly-used grain transfer method and are preferred by operators transferring damage-prone grain. Being a transportable unit, elevation angle is limited to the angle of repose of the grain. The angle of repose is a physical stacking property of a grain and varies between grain types. The repose angle is a measure of the angle of the sides of a conical grain pile from horizontal.

For example, the angle of repose for wheat is 27 degrees while canola is 22 degrees. Flow rates reduce as the angle of elevation increases to approach the repose angle. Belts are often cupped along the conveyor length to accommodate grain and hygiene is excellent with the design of a belted conveyor being self-cleaning. Bucket elevators are predominantly used to elevate grain vertically and are commonly used together with belted conveyors transferring grain horizontally, or splitters diverting grain down chutes through a gated manifold.

Bucket elevators are self-cleaning by design and are typically fixed position equipment Drag-chain conveyors or paddle conveyors use a series of paddles fixed to a loop of chain moving inside a conduit. Drag chains can elevate at any angle, including horizontal, and are largely self-cleaning, although corners of the chain-loop will normally require attention. Drag-chain conveyors are a permanent installation but are extendable for facility expansion.

Slick storage set-ups

Useful resources

- GRDC Grain storage extension project

Web www.storedgrain.com.au - Grain Trade Australia

Web www.graintrade.org.au

Grain storage specialists

- QLD and northern NSW

Philip Burrill (07) 4660 3620

Email philip.burrill@daff.qld.gov.au - Southern NSW, VIC, SA and TAS

Peter Botta 0417 501 890

Email pbotta@bigpond.com - Western Australia

Chris Newman 0428 934 509

Email chris.newman@agric.wa.gov.au

Grain biosecurity contacts

- Plant Health Australia

(02) 6215 7700

Email biosecurity@phau.com.au

Web www.planthealthaustralia.com.au

Silo Buyer’s Guide

The decision of which silo to buy can be daunting, mainly because it’s a 20+ year investment and not a purchase that is easily returned or traded-in if it proves unsuitable. The following information will help identify the key features to look for when purchasing silos.

Key Points

- Buying silos is a significant, long-term investment – take the time to make the right choice.

- Consider the storage requirements for the next 20 years — not just the next season.

- For reliable insect control and grain quality maintenance, choose a gas-tight sealable storage, which also has aeration.

- Gas-tight sealable storage must meet the Australian Standard AS2628.

Choose carefully: While all silos are made to store grain and ‘do the job’, some will

enable superior grain quality management than others.

Quality in – quality out

Maintaining grain quality during storage relies on the ability to control moisture, temperature and insects. It makes sense to look for storage with aeration cooling as well as being gas-tight sealable for effective fumigation.

While aeration cooling won’t reduce grain moisture significantly, it will prevent moisture migration and lower grain temperature. Properly managed aeration cooling provides cool, uniform conditions throughout the storage, which discourages pest infestation and mould growth and maintains grain quality. An added benefit of aeration is that it can be used to ventilate a silo after fumigation in one day, rather than waiting five days.

Insect pest control

Western Australia has given up access to contact pesticides long ago and the eastern states are under increasing pressure to follow suit to protect our markets. This puts added pressure on fumigants, mainly phosphine, to control pests during storage. In order to control pests at all life stages (eggs, larvae, pupae, adult) and prevent further resistance, phosphine and other fumigants are only effective in a gas-tight storage.

A little maintenance goes a long way

A little maintenance goes a long way

In the same way that all farm machinery needs regular maintenance to keep it working reliably, so do silos, especially gas-tight sealable silos. A small gas leak can mean the difference between a successful fumigation and insects surviving, leading to loads being rejected upon receival.

Grain hygiene is the other important maintenance component. Well designed silos won’t have areas that trap grain and dust making them quick and easy to clean.

Find a safe bet

Find a safe bet

The WHS (previously OH&S) spotlight continues to shine on agricultural industries and is undoubtedly here to stay. Consider silos that meet state WHS requirements and more importantly can be safely operated by everyone on site.

While some silos come without ladders, mould and insects are often found in the top of a silo before they can be detected at ground level. The main options are to have an WHS compliant ladder, use a safety harness or build a platform that spans along the top of a line of silos.

Silo purchase checklist

Copyright © All material published in this Fact Sheet is copyright protected and may not be reproduced in any form without written permission from the GRDC. Produced by: www.primarybusiness.com.au

Safe Storage of Sunflower Seed – Aeration Drying and Cooling

Grain Storage Fact Sheet February 2015

Results of aeration trials supported by the Australian Oilseed Federation Oilseed

Development Fund and the Australian Sunflower Association as part of the

Broadleaf Cropping Alliance, a Grains Research and Development Corporation funded

initiative.

Key Points:

- Aeration drying and cooling enables safe storage of sunflower seed across a broad range of moisture contents and ambient temperatures.

- Optimal sunflower seed storage occurs below 9 per cent MC at 40 per cent oil content. For higher oil contents (≥50 per cent), store sunflower seed at 7.5 per cent MC.

- Moisture content can be lowered two to three per cent in less than a week with aeration drying.

- Reliable aeration drying requires fan airflow rates in excess of 15 litres per second per tonne (L/s/t), while aeration cooling requires airflow rates of between 2 to 4 L/s/t.

- Aeration cooling fans can reduce seed temperatures in storage by more than 10°C in two to three days.

- Sunflower oil quality can be maintained with well-managed aeration drying and cooling systems.

A moisture content range of 7.5 – 9.0 per cent in storage, is optimal to reduce the risk of moulds and storage pests, while maintaining seed oil quality.

Aeration drying offers the flexibility to start harvest early (at high seed moisture contents) and the ability to harvest for more hours each day. Aeration cooling delivers cool, dry and uniform conditions during storage to maintain optimal seed quality.

Growers who successfully manage sunflower seed moisture and temperature during storage can build a reputation for supplying a consistent quality of sunflower seed that maximises market opportunities in the short and long term.

When designing storage systems, seek independent technical advice on the correct equipment and operating procedures.

On-farm trials support aeration drying

On-farm trials in three silos run by Department of Agriculture Fisheries and Forestry Queensland (DAFF QLD) revealed that using aeration drying at harvest can allow growers the flexibility to harvest sunflowers at high moisture contents (≥13 per cent MC) provided the appropriate size fans are used.

During the trial, the first small load of harvested sunflower seed delivered into the Kotzur silo was measured at 13.7 per cent MC. After subsequent loads, and prior to drying commencing, the bottom third of the silo averaged 12.6 per cent MC, the middle section 10.5 per cent MC and the top portion 9.6 per cent MC (see Figure 1).

After six days of aeration drying, the sunflower seed moisture content was reduced to 5.6 per cent at the bottom, 7.5 per cent in the middle and 9.4 per cent in the top section of the silo.

Note: Averaging silo moisture contents, drying could have ceased on day five to meet delivery standards.

Aeration drying equipment

Aeration drying requires airflow rates in the order of 15 to 25 L/s/t to reliably move drying fronts quickly through the full grain bulk.

For the DAFF QLD trial, a Kotzur drying silo of 75 m3 capacity, holding 27 t of sunflower seed was fitted with a DF 4000 7.5 kW three-phase fan to deliver the airflow rates of 25 to 30 L/s/t.

On a larger 140 m3 cone-based Grainmaster silo, two F650, 1.5 kW singlephase fans were retrofitted. The F650 fans delivered 17 L/s/t to dry 58 tonnes of seed.

High airflow rates can be achieved for drying partly because of the large size and low density (e.g. 41 kg/hL) of sunflower seed, which creates sizeable air gaps between seeds and reduces the back pressure the fans work against. Fan performance is reduced when used on smaller grains such as sorghum and canola, or when the fans work against greater depths of grain in a larger silo.

Drying fan operations

Fan run-times during the trial were managed using a GrainSafe 5000™ aeration controller. The aim was to push drying fronts completely through the full grain depth by maximising fan running hours each day.

During the first two days the controller was set to run fans while the ambient air was less than 75 per cent relative humidity (RH ). For the remaining four days the drying settings were altered to use all ambient air below 65 per cent RH .

Ambient air below 75 per cent RH is less than the equilibrium of 9 per cent MC of sunflowers. The second stage of drying using ambient air below 65 per cent RH drives towards moisture contents of less than 8 per cent (see Table 1).

Regular sampling is required to ensure seed is not over dried.

Cost of drying

As ambient conditions for aeration drying vary, a conservative estimate of six days has been used to calculate the cost of drying during the trial.

Over the six days the fan run-time totalled 67 hours. Using a charge rate of $2.10 per hour to run the 7.5 kW fan, this indicates total electricity costs of $140 to dry the 27 t of seed — approximately $5/t.

Benefits of aeration drying

The flexibility to harvest sunflowers early and deal with high seed moisture content has numerous advantages including:

- reduced risk of weather damage to the standing crop;

- less fire risk in harvesters or grain dryers;

- extended harvest days and the ability to resume more quickly after rain events, and

- maximised saleable tonnage and income by limiting over-dry sunflower seed towards the end of harvest.

Managing admixture

Aim to start harvesting sunflower seed when moisture content is in the range of 10 – 12 per cent and check for acceptable admixture levels in the seed sample. Aim for no more than 2 per cent admixture and keep below the 4 per cent maximum receival limit. Watch for fine admixture in the sample. Incorporating a perforated section in the harvester outload auger and other augers can reduce admixture fines.

Cooling during storage

In addition to the use of drying fans at harvest to manage high-moisture seed, aeration cooling during storage, using low airflow rates of 2 to 4 L/s/t, can be used to reduce seed temperature and create uniform moisture conditions throughout the storage bulk. This reduces the risk of moulds, storage pests and seed oil quality deterioration.

Aeration cooling trial

During March on the Darling Downs, 65 t of monounsaturated sunflower seed was harvested at between 8 to 9% MC and stored in an aerated 158 m³ capacity cone-based silo.

The silo was fitted with two standard, single-phase 0.37 kW aeration cooling fans (F370) providing 7 L/s/t airflow. Sunflower seed has a lower back pressure than other grains, so the cooling airflow rate for this trial was above the typical 2 to 4 L/s/t.

Cooling fan operations

A Grainsafe 5000™ controller set aeration fans to run through its automatic cooling management program. Typically, this is an initial five days of continuous fan run time, followed by a purge fan run of seven days taking 9 to 12 hours per day of cool air, concluded by the longer term protect fan setting. In most cases, the protect setting runs fans for about 100 hours per month, selecting the best available ambient air. To protect grain, all cooling settings automatically stop fans during times of air humidity above 85 per cent (RH ).

Cooling results

Sunflower seed temperature in the silo was monitored continuously for six weeks from mid-March into April.

Prior to aeration, harvested seed temperatures in storage were above 35°C (see Figure 2). Two days of aeration reduced seed temperature by 10°C to less than 25°C.

With warm ambient temperatures during the second week of aeration, seed temperatures rose briefly. By week four seed temperatures fell to 20°C, then finally to less than 15°C by week six.

Sunflower oil quality

High-quality monounsaturated oil is the major end product for sunflower seed in Australia, so it is important to maintain oil quality during storage and handling.

Poor seed storage conditions, which expose sunflower seed to excess moisture and heat, can degrade oil quality by raising levels of free fatty acids (FF A).

During the aeration drying and cooling trials outlined here, sunflower seed was sampled before and after storage from all silos.

Samples were submitted for analysis and the results demonstrated no increase of FF A levels as a result of aeration drying or cooling (see Table 2.)

Further reading

Safe Storage of Sunflowers, www.bettersunflowers.com.au/bysp/storage

The Big Yellow Sunflower Pack Module 7 Safe storage, https://bettersunflowers.com.au/public/safestorage/#/0

Dealing with high-moisture grain (GRD C Fact Sheet), www.storedgrain.com.au/dealing-withhigh- moisture-grain/

Aerating Stored Grain – Cooling or Drying for Quality Control (GRD C Booklet), www.storedgrain.com.au/aeratingstored- grain/

Storing oilseeds (GRD C Fact Sheet), www.storedgrain.com.au/storingoilseeds/

Grain storage specialists

Philip Burrill

1800 933 845

Email: philip.burrill@daff.qld.gov.au

Authors:

Philip Burrill DAFF Qld,

Andrew Ridley DAFF Qld.

Acknowledgements:

Rob and John Piper and families, “Itchelby” Felton.

Mark Conway, Control Unlimited P/L.

Alan Andrews, Customvac P/L.

Kevin Charlesworth, “Mirradong” Clifton.

Liz Alexander, Blue Dog Agribusiness, Emerald.

The aeration trials were supported by the Australian Oilseeds Federation (AOF) Oilseed Development Fund and the Australian Sunflower Association as part of the Broadleaf Cropping Alliance, a Grains Research Development Corporation funded initiative.

Aeration cooling for pest control

Grain aeration provides growers with a powerful tool to maintain grain quality during harvest and storage. Aeration cooling may not eliminate the need for chemical insect control, but it will dramatically slow insect development.

Key Points

- Grain temperatures below 20°C significantly reduce mould and insect development.

- Reducing grain temperature with aeration cooling protects seed viability.

- Controlling aeration cooling is a three-stage process — continual, rapid and then maintenance.

- Stop aeration if ambient, relative humidity exceeds 85 per cent.

- Automatic grain aeration controllers that select optimum fan run times provide the most reliable results.

Aeration cooling for pest control

While adult insects can still survive at low temperatures, most young storage pests stop developing at temperatures below 18–20°C (see Table 1).

At temperatures below 15°C the common rice weevil stops developing.

At low temperatures insect pest life cycles (egg, larvae, pupae and adult) are lengthened from the typical four weeks at warm temperatures (30-35°C) to 12-17 weeks at cooler temperatures (20-23°C).

An effective insulator

Without aeration, grain is an effective insulator and will maintain its warm harvest temperature for a long time.

Like housing insulation, grain holds many tiny pockets of air within a stack — 100 tonnes of barley requires a silo with a volume of about 130 cubic metres, 80m3 is taken up by grain and the remaining 50m3 (38 per cent) is air space around each grain.

Seed viability

Research trials reveal that wheat at 12 per cent moisture content stored for six months at 30-35°C (unaerated grain temperature) will have reduced germination percentage and seedling vigour.

Aeration cooling

Aeration cooling can be achieved with air-flow rates of 2–3 litres per second per tonne delivered from fans driven by a 0.37 kilowatt (0.5 horsepower) electric motor for silos around 100t.

Research carried out by the Department of Agriculture, Fisheries and Forestry (DAFF), Queensland shows that with the support of an aeration controller, aeration can rapidly reduce stored grain temperatures to a level that helps maintain grain quality and inhibits insect development.

During trials where grain was harvested at 30°C and 15.5 per cent moisture, grain temperatures rose to 40°C within hours of being put into storage.

An aeration controller was used to rapidly cool grain to 20°C and then hold the grain between 17–24°C during November through to March.

Before replicating similar results on farm, growers need to:

- Know the capacity of their existing aeration system.

- Determine whether grain requires drying before cooling can be carried out.

- Understand the effects of relative humidity and temperature when aerating stored grain.

- Determine the target conditions for the stored grain.

Air used for cooling grain

Varying ambient conditions affect stored grain differently depending on the combination of temperature and relative humidity outside the silo and the temperature and moisture content of the stored grain (see Table 2).

Grain with a higher moisture content can be cooled quickly with low-humidity air due to the evaporative cooling effect that occurs inside the storage.

The relative humidity of the ambient air affects the efficiency of grain cooling.

In an ideal world we would select air for cooling that is low in temperature and relative humidity, but these conditions rarely occur.

Air movement within the stack

Grain at the top of the stack is the hottest, as heat rises through the grain and it is exposed to the head space in the silo (see Figure 1).

As the air in the head space heats and cools each day, it creates ideal conditions for condensation to form and wet the grain on the top of the stack.

Be aware aeration drying requires specifically-designed equipment and the process is much slower than aeration cooling or hot-air drying.

The cooling process

Operating an aeration fan for cooling requires a planned control program, which is best done with an automatic aeration controller.

But even without an aeration controller growers need to aim for the same run time, following the same process.

Without aeration, grain typically increases in temperature immediately after it enters the storage.

The initial aim is to get maximum air-flow through the grain bulk as soon as it enters storage, to stop it from sweating and heating.

When first loading grain into storage, run the aeration fans continuously from the time the grain covers the aeration ducts for the next 1-3 days, until the cooling front reaches the top of the storage.

However, do not operate the aeration fans on continuous mode if the ambient relative humidity is higher than 85 per cent for extended periods of time as this will wet the grain.

After the aeration fans have been running continuously for 2–3 days to flush out any warm, humid air, reduce run time to 9–12 hours per day during the coolest period, for the next seven days.

The goal is to quickly reduce the grain temperature from the mid 30s°C down to the low 20s°C.

An initial reduction in grain temperature of 10°C ensures grain is less prone to damage and insect attack, while further cooling becomes a more precise task. During this final stage, automated aeration controllers generally run fans during the coolest periods of the day, averaging 100 hours per month.

Grain temperature is gradually reduced as low as possible and then maintained throughout the storage period.

The risks of getting it wrong

Running aeration fans on timers that are pre-set for the same time each day will not ensure the selection of the most appropriate air for grain quality maintenance.

The biggest risk with running aeration fans without a controller is forgetting or not being available to turn fans off if the relative humidity exceeds 85 per cent.

Operating fans for extended periods of a few hours or days in humid conditions can increase grain moisture and cause moulding.

Aeration controllers are designed to automatically select the best time to run aeration fans. Fans on these systems only run when the conditions will benefit the stored grain.

Cooling or drying — making a choice

Knowing whether grain needs to be dried or cooled can be confusing but there are some simple rules of thumb.

For longer-term storage grain must be lowered to the correct moisture content.

Grain that is dry enough to meet specifications for sale (12.5 per cent for wheat or 13.5 per cent for sorghum) can be cooled, without drying, to slow insect development and maintain quality.

Grain of moderate moisture (up to 15 per cent for wheat and sorghum)

can be either cooled for short periods to slow mould and insect development or, dried providing the right equipment and conditions are available.

After drying to the required moisture content, grain can be cooled to maintain quality.

High-moisture grain (for example, 16 per cent or more for wheat and sorghum) will require immediate moisture reduction before cooling for maintenance.

Installation and maintenance tips

When retrofitting an aeration system, avoid splitting air-flow from one fan to more than one storage. Each storage will provide

a different amount of back-pressure on the fan resulting in uneven air-flow and inefficient or even ineffective cooling.

If buying an aeration controller be aware that most controllers need to be installed by an electrician.

The preferred mounting location for aeration controllers is outside where the sensors can get ambient condition readings but are sheltered from the direct elements of the weather.

To avoid the chance of a dust explosion, avoid installing aeration controllers in a confined space.

Ensure your electrician installs wiring properly insulated and protected from potentially-damaging equipment, such as augers.

Monitoring a must

Aeration controllers reduce the amount of time operators need to physically monitor grain storages and turn fans on and off, but units and storage facilities still need to be checked regularly.

Most controllers have hour meters fitted so run times can be checked to ensure they are within range of the expected total average hours per month.

Check fans to ensure they are connected and operating correctly.

The smell of the air leaving the storage is one of the most reliable indicators if the system is working or not.

The exhausted air should change from a humid, warm smell to a fresh smell after the initial cooling front has passed through the grain.

Animals can damage power leads and automatic controller sensors and fan blades or bearings can fail, so check these components regularly.

Check for suction in and feel for air-flow out of the storage vents when the fans are running.

Keeping grain at the right moisture and temperature levels will reduce the likelihood of insect infestations, but stored grain still needs to be sampled regularly and monitored for any changes.

If possible, safely check the moisture and temperature of the grain at the bottom and top of the stack regularly.